Given energy saving, environmental protection and performance, lightweight vehicles have become one of the important directions for the development of the global New Energy automotive industry. Up to date almost all major automakers have proposed goals of promoting the development of new energy vehicles that we can forecast a wide application of magnesium alloy die casting parts with the rapid development of new energy vehicles and the acceleration of the lightweight vehicle process.

Magnesium’s use in automotive applications has grown in popularity over the last 10 years as a result of growing environmental and governmental pressures. The challenges of fuel efficiency, increased performance, and sustainability are at the forefront of people’s minds. In addition, China released Energy-saving and New Energy Vehicle Technology Roadmap 2.0, putting forward lightweight requirements for all types of vehicles.

- The key advantages of Magnesium alloy

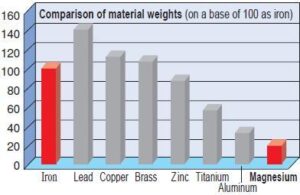

- Light weight. The density of magnesium alloy is only 1.74g/ cm³, 36% lighter than aluminum alloy, 77% lighter than steel. The use of magnesium alloy can greatly reduce the weight of the vehicle body, thus indirectly reduce fuel consumption.

- High strength. The specific strength of magnesium alloy is better than steel and aluminum alloy, and the specific stiffness is also the same as the two. So magnesium alloy can be applied to the occasion of shock vibration load.

- Great casting and cutting performance. The magnesium alloy has very good casting property and processing performance. The minimum wall thickness of magnesium alloy die casting is as low as 0.6 mm and for aluminum alloy is 1.2-1.5 mm. Besides, magnesium alloy die casting components is easy to follow-up machining with excellent dimensional stability.

- Excellent damping functions. The damping effect of magnesium alloy is better than aluminum alloy and steel, very suitable for the production of automotive seat frames, gearboxes and steering wheels, which helps enhance the safety and comfort of the car driving.

- The main disadvantages of Magnesium alloy

Of course, there is no perfect thing in the world. Due to the various characteristics of magnesium alloy material itself, there are still some technical problems to be solved making its further application in the automotive industry. Below are three main aspects:

- Strength is not high enough to be used as a structural material for vehicles.

- Easy to generate creep under high temperature, which cannot meet the sealing requirements of housing system.

- Low corrosion resistance that fails to meet the application under coastal climate conditions.

Provided that the above problems cannot be solved, magnesium alloy is impossible to obtain a wide range of applications in the automotive industry. Therefore, it is necessary to improve the composition of magnesium alloy and its processing technology and related. According to the industry report, scientific researchers initially proposed the corresponding solutions, including high toughness magnesium alloy, heat-resistant magnesium alloy and corrosion-resistant magnesium alloy. Further progress is to follow.

- Magnesium alloy boosts lightweight new energy vehicles

Currently, there are three categories of lightweight new energy vehicle technology: lightweight material technology, lightweight advanced process technology, and lightweight structure optimization technology. It is critical research and development in identifying and executing the enabling technologies to significantly reduce vehicle weight for interior and structural components. New Energy vehicles that are lightweight rely on lightweight materials.

The average cruising range of new energy vehicles can rise by 5-8% for every 10% reduction in weight. As a result, there is a pressing need for lightweight new energy vehicles. Magnesium alloy has a density of 2/3 that of aluminum and 1/4 that of steel, so it is far lighter than the latter two, making it the greatest choice for lightweight new energy vehicles.

Because battery packs account for more than 20% of the weight of new energy vehicles, to lightweight the vehicles actually relies a lot on how to reduce weight of battery packs. Less weight in outer casings, bottom trays, and inner end/side panels can all contribute to lighter battery packs. For example, the Tesla MODEL S’s battery pack casing is mostly made of aluminum alloy, which weighs up to 125 kg, and if it were made of magnesium alloy, the weight would be decreased by roughly 60 kg, nearly 50% reduced.

By choosing magnesium alloy from a variety of advanced lightweight materials, the research experts are driving breakthroughs to build lighter components for automotive industry that are both environment friendly and performance concerned. As automotive engineers redesign an entire industry, strategic use of magnesium components facilitates this exciting transformation.

Conclusion

Magnesium alloy’s application in new energy automotive industry can give benefits beyond weight reduction. The desire to identify challenges, solutions, and possibilities related to the usage of magnesium in cars has been rising for the past years. Magnesium usage on the front end of a vehicle not only reduces the total weight of the vehicle, but it also allows the center of gravity to be shifted to the rear, increasing handling and turning capabilities. Furthermore, transfering magnesium parts can result in frequencies that reduce vibration and overall noise. Steel and aluminum components in automobiles can be replaced with a single die casting piece of magnesium alloy that requires less tooling and gauges, resulting in lower manufacturing cost.

ONE-STOP Contract Manufacturing Solutions @GEMS-MFG.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

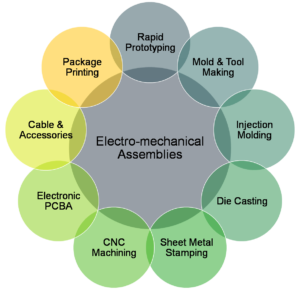

GEMS Manufacturing Ltd, based in Shenzhen China, have been providing Custom Metal, Plastic, Rubber & Electronic Part and Electro-mechanical Assembly Integration Services, which allows our customers to find all their manufacturing needs in one place. At GEMS we understand the importance of cost down manufacturing with flexible solutions, joining us with the industry’s best network of manufacturing talents, tools and facilities. Up-to-date we have shipped hundreds of containers to USA, UK, EURO and other oversea markets.

To learn more about how GEMS Manufacturing can help improve your manufacturing timelines for Integrated Product Development (IPD) and resolve your supply chain challenges, contact us or request a quote when needed.