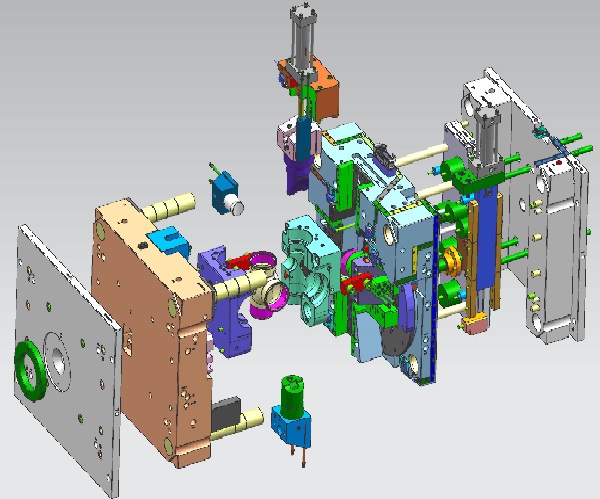

Tool and Mold Making in Shenzhen, China

— Tool and Mold Making is a very important aspect of manufacturing processes and cannot be taken lightly, as quality part always requires a quality steel mold or tool to generate! The tool is at the heart of the manufacturing process. If properly designed and constructed, a mold will be the key to efficiently producing plastics or metal parts throughout the entire life of the project.

With our experienced toolmakers, GEMS Manufacturing make every stage of tooling management more effective and straightforward – from planning and concept development, through to mold trial, testing, modification and production launch. After the tooling is made and parts are run it doesn’t end there. GEMS has a rigorous maintenance program that keeps the expensive asset clean and healthy, so it will last for the duration of the product lifetime which could be 3-10 years. We are the right mold manufacturer who can well protect your tool to go the extra mile is a priority.