An Elevated Approach to Project Management @GEMS-MFG

Whether you’re launching a new product or fine-turning an existing model to meet market tendency, GEMS-MFG’ project management methods will proactively mitigate your risks and strategically plan the fastest path to market. At GEMS-MFG we custom our Integrated Product Development strategy to fulfill your demand, incorporating measures to proactively minimize your risks and strategically plan the quickest path to commercialization.

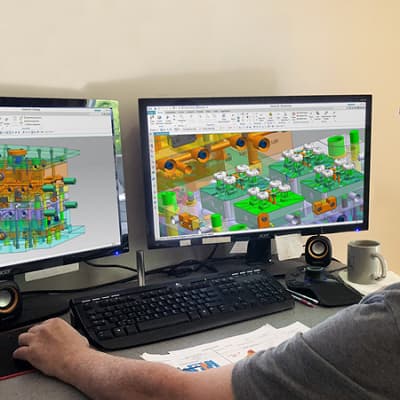

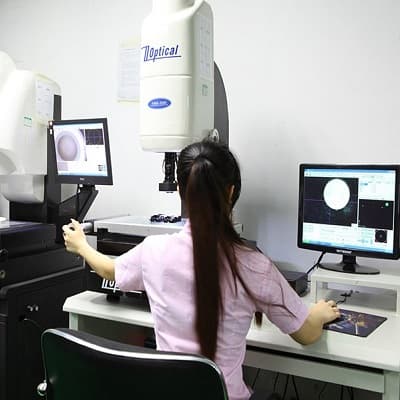

At GEMS Manufacturing our strong project management brings together all aspects of product development: design, manufacturing, industry considerations, quality standards, and regulatory compliance.

Our goal for every project is to provide the optimal balance of services, facility possibilities and technical expertise to meet our customers’ demands. From design to prototype, to new product introduction, full-scale manufacturing and beyond, we support the full services of Integrated Product Development (IPD). Our staff understand the importance of being adaptable and responsive to our consumers.

At GEMS Manufacturing our project management is featuring with below key points that we are willing to share with.

1. Early engagement with project start

Early involvement and close collaboration are key to our project management methodology. We’ve found that talking with our project manager at the start of the project resulted in more efficient and reliable production solutions, shorter time to market, and high-quality products. In short, a product that is more competitive to launch.

2. Allocate responsible project manager

As part of our commitment to excellence, performance and care, you will have a dedicated project manager who remains the primary contact throughout the entire project. Our project managers are in charge of allocating the appropriate competencies and abilities, leading the team and reaching project milestones, so as to guarantee that the project runs smoothly as planned.

3. Regular project meeting recap and plan

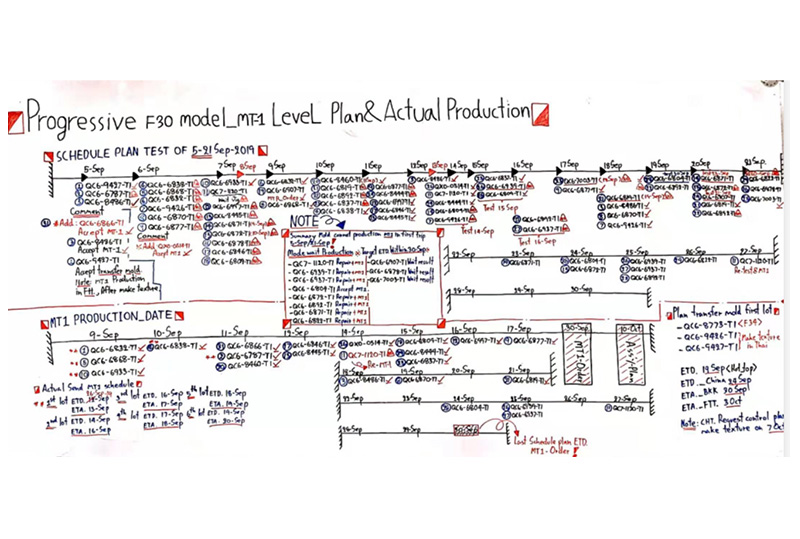

While keeping a sharp eye on the deadlines, our project manager leads a team of technical, production, and supply chain professionals who work directly with the customer to develop efficiency. Weekly project management meetings and timely interaction with the customer’s team result in open and smooth mutual communication, ensuring that all parties are up to date on the latest progress. Direct involvement in trials and testing allows us to iterate the design as we discover areas for improvement or as requirements grow, allowing us to further refine customer expectations and end users’ experiences.

4. Budget control and cost saving

Budgets for product development are becoming increasingly tight-controlled, and OEMs require a proficient partner who can help them cut costs where they can. We leverage our excellent project management and systematic procedures to make the right decisions early in the design of your product to avoid accumulating unexpected expenses over time. With our in-depth analysis of value, function and supplier involvement, we can find savings in material and component optimization, as well as supplier engagement, and we can pass those saving back to you. We’re able to manage the project and work with approved vendors in a cost-effective and timely manner because of our component engineering skills and extensive supply chain understanding. This also allows us to better management the product lifecycle by anticipating component obsolescence or fit-to-form functionality ahead of time. Each of these factors is crucial in ensuring that the right component is used in your final product at the right price.

5. Close communication

From concept to completion, GEMS-MFG works with customers to bring their product visions to life quickly and profitably. We’re experts at tackling on challenged problems and providing high-quality solutions at scale. GEMS’s tried-and-true method to new product introduction is repeatable, scalable, and reliable. We believe in communication transparency and on-time delivery. We provide convinced proof at each stage of your product’s lifecycle by staging checkpoints to guarantee that relevant actions are taken to assure the quality and reliability of your product, program, or project.

6. Ultimate productity tools

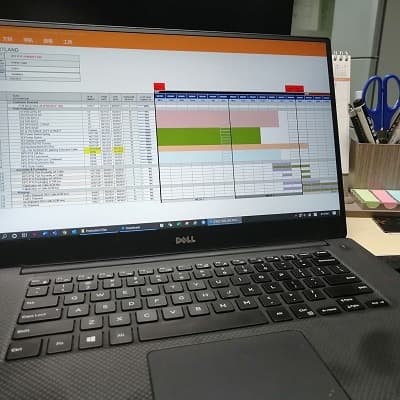

To achieve excellent project management, we use a variety of organizational and information-sharing tools:

- Organization Matrix – Separate Program Management and Resource Teams

- Enterprise – Wide Project Management System

- Weekly Resource Allocation Meeting

- Program Milestone and Deliverables Tracking

- Extensive Templates and Forms

- Agile Configuration Management

- System for Corrective / Preventative Action

Conclusion

To sum up, GEMS Manufacturing excels in the dynamic realm of project management, providing a finely tuned approach that guides clients seamlessly through the complexities of design and engineering. Our Integrated Product Development (IPD) strategy is a testament to our commitment to proactive project management, ensuring meticulous risk mitigation and an expedited path to market, whether unveiling a new product or refining an existing one. With dedicated project managers at the helm, early engagement, regular meetings, and transparent communication are not just practices but principles embedded in our project management methodology. Meticulous budget control and strategic cost-saving measures form the core of our commitment to efficient project management. GEMS-MFG stands as a reliable partner, committed to delivering excellence in design, engineering, and every facet of the project management lifecycle. Our ultimate productivity tools and unwavering dedication to close collaboration underscore our mission to set new standards in efficient and profitable project management, making us the preferred choice for navigating success in the competitive landscape of manufacturing.