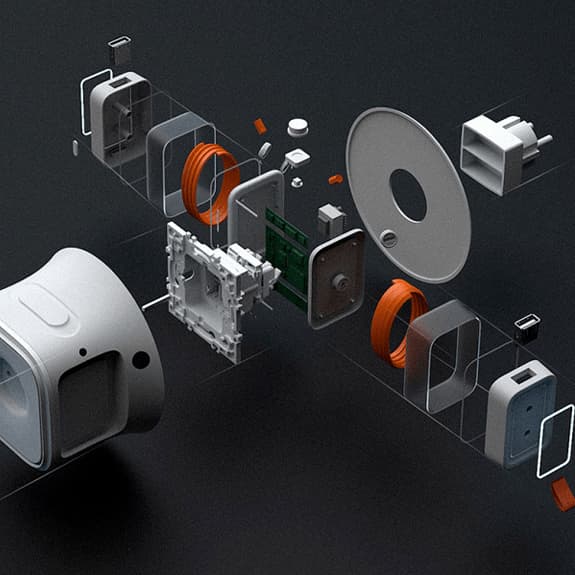

Electronic & Mechanical Products’ Finished Assembly in Shenzhen, China

— Assembly is the final stage of production before your product reaches your customers, so getting it right is extremely critical. GEMS ensures that your customers have a great first experience of your finished product by utilizing innovative technology as part of an integrated manufacturing solution. Of course, we can manage your project from start to finish covering the complete product life cycle. We specialize in collaborating closely with our clients to bring their ideas to life.

GEMS is a great global provider of high-precision plastics and metal components, as well as electronic assemblies. From design support through finishing and final assembly, we serve customers all around the world, delivering quality, cost, and production solutions based on a relentless commitment to continuous improvement. Our build-to-print, prototyping, tooling and massive fabrication services are well-suited for clients of all sizes and types. Whether your business is large or little, and whether your order is for a few parts or a few million, GEMS can gladly take care your contract assembly needs.