Partnering with a RIGHT contract manufacturing provider comes with a long list of advantages, including time and cost savings from a full range of capabilities performed by a team of highly qualified specialists. These benefits from such contract manufacturing services can help you find unique solutions to fast grow your revenue and mitigate risks throughout the supply chain and more. Although you are most likely looking for a vendor primarily for their manufacturing machines and facilities, there are Top 4 services in the perspective of capabilities that you can’t neglect but will support you throughout each project from conception to completion.

Ultimately, your goal is to find a contract manufacturing partner capable of providing you with “the quality product on time and at budget”. To learn more about the subject Top 4 services and their benefits, read on.

#1 Cost Savings

The first reason to consider contract manufacturing is simply all about COST. Primarily, contract manufacturing makes it easier for a company to produce its products without having to take on considerable overhead. If you authorize and outsource some operations to the right manufacturing partner, you may save a ton of money that a survey shows industries can cut production costs by average rate 35% when they worked with contract manufacturer in China. What’s your goal saving number with the contract manufacturing partner like GEMS-MFG?

The reason why contract manufacturing can cut so much from your existing purchasing costs is because contract manufacturers already have the complete line of resources like facilities, equipment, technology, and fully-trained staff to handle your specific task. It eliminates the overhead associated with investing in machinery, materials and additional labor and it also streamlines the production supply chain and simplifies the manufacturing process. Typically, they manage all the jobs under one roof assigning each task to the corresponding parties who specialize in efficiency, cutting-edge methods and saving you cash to the maximum.

However, please allow me to highlight your attention that searching around for the lowest quote can be a flawed strategy and cause you unexpected loss. Your contract manufacturing partner is supposed to offer competitive prices and save your company money, but normally they won’t run the business at a loss. While you should of course request an enquiry, the quote may not necessarily tell the whole story. Take into account the entire picture and select a contract manufacturing partner based on all important factors.

#2 Technical support

An experienced, highly skilled contract manufacturing partner should provide you with more than designs for your component. They should also be able to analyze your designs and make professional recommendations on how to develop the most dynamic, functional precision component designs possible. Typically, the client seeking outsourced product will provide a 3D CAD of the parts for reviewing. From there, the contract manufacturer will proceed DFM (Design for Manufacturing) of the components, subject to client approval, after which begins the pre-production process before mold steel cutting.

Another sign of technical support for a good contract manufacturing partner is their ability to work with different types of raw materials, such as metal, plastic, silicone and electronic materials, which are produced using highly customized processes and require unique compliance testings. For such a specialized practice, it requires manufacturing experts in the field. Plus, it is recommended to collaborate with a contract manufacturer who can show its versatility by providing a portfolio of clients in different industries that need different components, which means a variety of tools and skill sets are required of the company.

There is NO surprise to see that the customer clearly knows the product expectation imaging in his mind, but he has little knowledge in manufacturing processes how to build the design into reality. With the strong technical support from your contract manufacturing partner, they can guide you on the best materials, processes and applications, which will reduce new product development barriers by solving potential problems and minimizing risks, thereby maximizing your profits.

#3 Quality Control

Quality control refers to a set of quality management’s policies, processes, and procedures for planning and production by a contract manufacturer. It is created basing on solid business sense and practices, and in essence it is an organization’s core business focus. The capability for quality control should be at the top of the list when looking for a contract manufacturing partner.

Assuming you already have inspection equipments in place to monitor and ensure product quality, to select the right contract manufacturer will add an extra set of eyes to your manufacturing process, doubling the quality levels for your production output. Contract manufacturing essentially doubles the amount of brainpower, oversight and handling that goes into quality control. As a result, products are not only supplied in more efficient, but also better.

A reliable contract manufacturer follows external quality control requirements outlined in the license to trade and customer guidelines. It also achieves the following:

- Documents requirements in the management system

- Documents proper employee training

- Measures, monitors and reports compliance of the processes

- Analysis of system processes to determine correct actions

- Sets up plans for audits and performance review

#4 Scaled Production

This can be one critical advantage to gain your interest in contract manufacturing to start with. Scaling up is the holy grail of the manufacturing industry! What works now in small quantity may not convert to the same level of success on a larger scale. Contract manufacturing partner like GEMS in China, on the other hand, eliminates this consideration to a large extent, as these factories are used to adjusting batch sizes, shortening lead times and maintaining high quality & efficiency standards across the board.

Smaller and mid-sized businesses frequently have the resources to manage contract manufacturing partners remotely, while running the production in-house is way more challenging. Because acquiring and storing facilities for operations of this size can be difficult, let alone the experience and expertise required for integrated product development (IPD), obviously contract manufacturing offers particular advantages to start-ups, smaller and medium-sized companies.

Usually professional contract manufacturers are highly specialized and streamlined for scaling up your production using cutting-edge technologies, techniques, and equipment. Many people employ lean manufacturing to reduce the impacts of scaling.

Conclusion

Choosing the right contract manufacturing partner can be a time-consuming and difficult task. There are multiple aspects to consider, many questions to ask, and numerous conversations to have. Following above guide is to ensure that all of your bases are covered in a simple and easy understanding manner. Clients who follow these principles will likely find it easier to select the proper contract manufacturing partner, enjoying greater quality, efficiency, productivity, adaptability and profitability.

To sum up, partnering with a trustworthy contract manufacturing partner includes more than just the production of components. At GEMS Manufacturing, we keep focus on Top 4 services – Cost Saving, Technical Support, Quality Control and Scaled Production, so that no project falls outside of our scope and the customer expectations are always well fulfilled or even exceeded.

ONE-STOP Contract Manufacturing Solutions @GEMS-MFG.

ONE-STOP Contract Manufacturing Solutions @GEMS-MFG.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

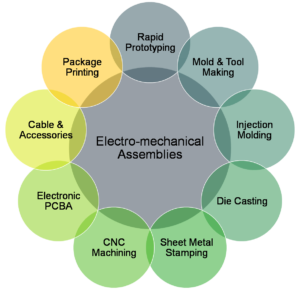

GEMS Manufacturing Ltd, based in Shenzhen China, have been providing Custom Metal, Plastic, Rubber & Electronic Part and Electro-mechanical Assembly Integration Services, which allows our customers to find all their manufacturing needs in one place. At GEMS we understand the importance of cost down manufacturing with flexible solutions, joining us with the industry’s best network of manufacturing talents, tools and facilities. Up-to-date we have shipped hundreds of containers to USA, UK, EURO and other oversea markets.

To learn more about how GEMS Manufacturing can help improve your manufacturing timelines for Integrated Product Development (IPD) and resolve your supply chain challenges, contact us or request a quote when needed.