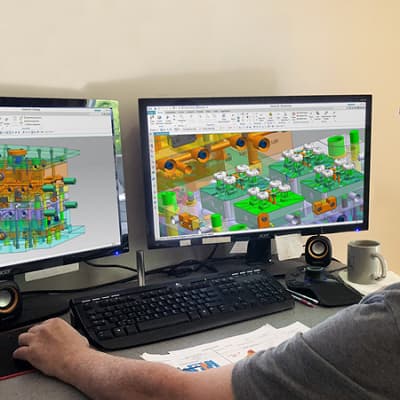

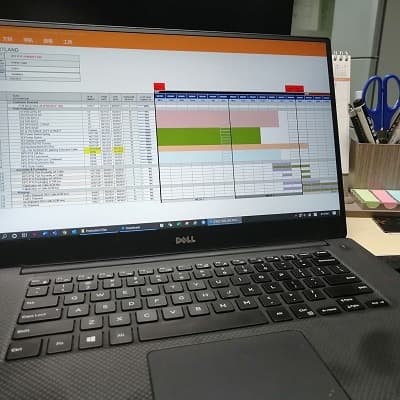

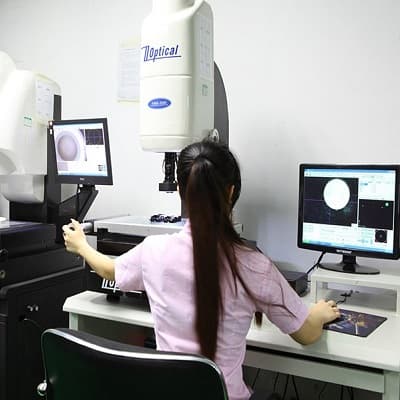

GEMS-MFG is an one-stop integrated solution provider for our customers’ out-sourced printed circuit board assembly and electronic manufacturing needs. Plus our services including electronic engineering, plastic and silicone injection molding, die casting, sheet metal forming, product assembly, testing and final box build, we are recognized as one of the leading electro-mechanical manufacturers.

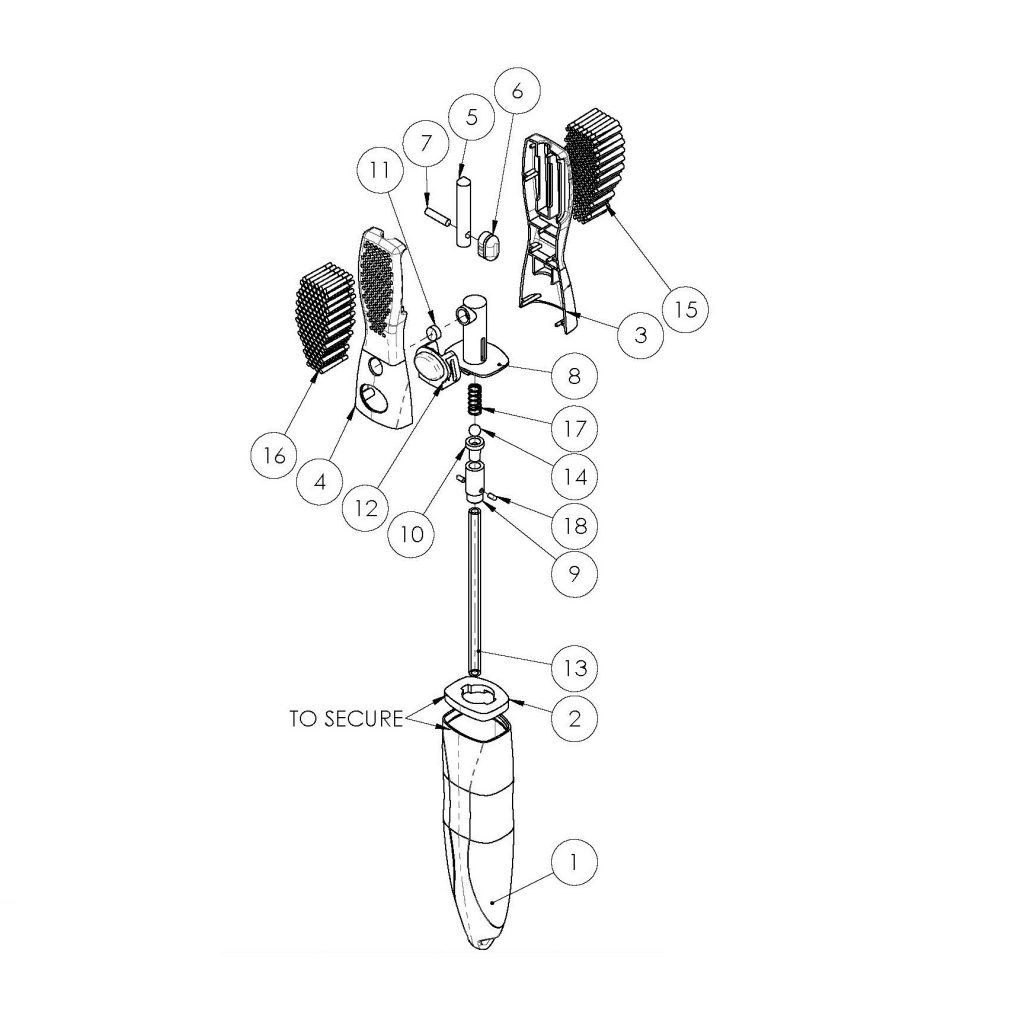

While providing a wide selection of product assembly options, GEMS-MFG always delivers products on-time, to-specification and in-budget. Our high-performance manufacturing processes and quality control system are designed to have incredibly tight tolerances, super-accurate repeatability and low energy consumption. We are able to provide a diversified range of assembly units for a wide range of industries, including electronics, automotive, medical, personal care and many more.

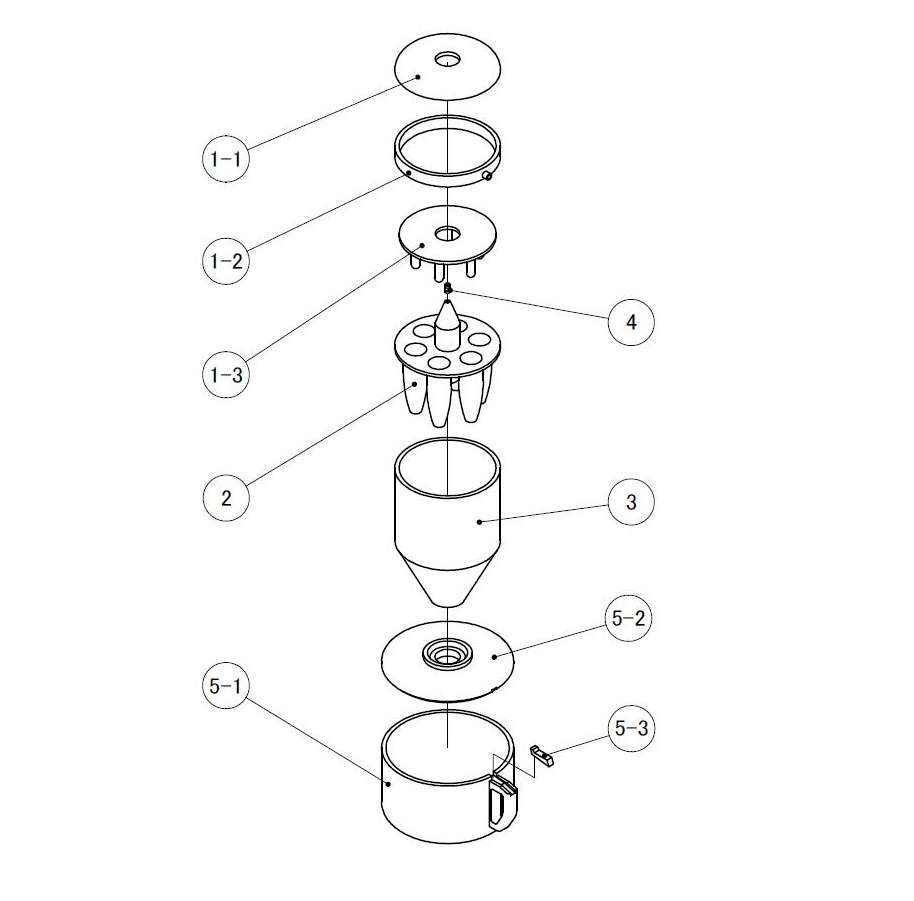

ASSEMBLIES

ASSEMBLIES PCBA

PCBA CABLES

CABLES PACKAGING

PACKAGING