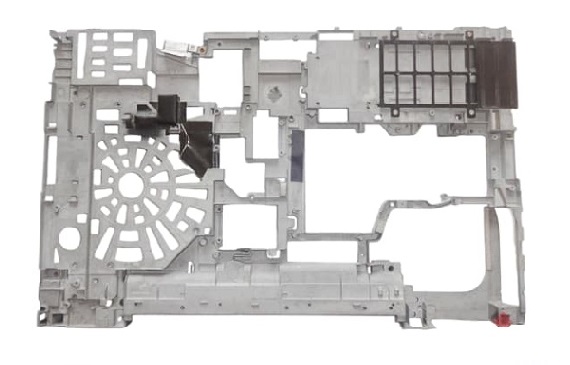

Magnesium Die Casting

Die casting is a manufacturing process in which molten metal is injected into a mold cavity under high pressure. Magnesium die casting specifically involves the use of magnesium alloy as the material. Magnesium alloys are lightweight and have good strength-to-weight ratios, making them suitable for applications where weight is a critical factor. Common magnesium alloys used in die casting include AZ91D, AM60B, and AM50A, while AZ91D is the most popular one for various industries’ application. It offers very good castability and toughness, and is an ideal material for light weight, highly durable parts.

Magnesium is the light-weight champion of all die casting metals. If your project requires a lightweight die casting component with an excellent strength-to-weight ratio, magnesium die casting is the logical option. GEMS-MFG specializes in die casting magnesium alloy AZ91D, a high-purity alloy prized for its corrosion resistance and a host of additional advantages:

- Longer Tool Life: AZ91D enhances the longevity of tools employed in the die casting process.

- Ease of Machining: Recognized as the easiest alloy to machine, AZ91D ensures efficient and precise manufacturing processes.

- Thermal and Electrical Conductivity: The alloy exhibits commendable thermal and electrical conductivity, adding to its versatility.

- Ideal for Thin-Wall, Complex Parts: AZ91D excels in the creation of intricate, thin-walled components, showcasing its adaptability.

- Noise and Vibration Dampening: The alloy’s excellent noise and vibration dampening properties enhance the overall performance of the cast parts.

- EMI & RFI Shielding: AZ91D provides robust electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding capabilities.

- Superior Finishing Characteristics: The alloy facilitates impeccable surface finishes, meeting high aesthetic standards.

- Remarkable Lightweight Properties: Magnesium’s weight is a mere 75% of steel and 33% lighter than aluminum, without compromising on strength.

- Eco-Friendly Recycling: Magnesium parts scrap material is 100% recyclable, aligning with sustainability goals.

In-Depth Exploration on Magnesium Alloy’s Unique Properties

In delving deeper into the unique properties of magnesium alloys, it becomes evident that their application extends beyond mere weight reduction. Magnesium alloys, exemplified by AZ91D, AM60B, and AM50A, boast a distinctive set of characteristics that elevate them to the forefront of die casting materials.

- High Strength-to-Weight Ratio: Magnesium alloys are renowned for their impressive strength-to-weight ratios, making them indispensable for applications where minimizing mass is critical. This characteristic is particularly advantageous in industries such as automotive, aerospace, and electronics.

- Superior Castability: Among die casting metals, magnesium alloys, especially AZ91D, exhibit outstanding castability. This facilitates intricate and complex designs, allowing manufacturers to create components with precision and efficiency.

- Thermal Conductivity: The commendable thermal conductivity of magnesium alloys enhances their suitability for applications requiring effective heat dissipation. This property is crucial in industries where managing temperature fluctuations is essential, such as in electronic devices and automotive components.

- Electrical Conductivity: Magnesium alloys, including AZ91D, feature good electrical conductivity. This makes them suitable for applications where efficient electrical transfer is necessary, expanding their utility in diverse electronic and electrical components.

- Noise and Vibration Dampening: The inherent ability of magnesium alloys to dampen noise and vibrations contributes to their adoption in products where minimizing sound and vibrations is imperative. This is particularly valuable in automotive and consumer electronics applications.

- EMI & RFI Shielding: Magnesium alloys, such as AZ91D, offer robust electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding. This property is essential in electronic devices to prevent interference and ensure optimal performance.

- Superior Machinability: AZ91D, recognized as the easiest alloy to machine, facilitates streamlined manufacturing processes. This results in cost-effective production and the creation of intricately detailed components.

- Environmental Sustainability: The recyclability of magnesium alloy scrap material aligns with eco-friendly practices. Choosing magnesium for die casting contributes to a circular economy by reducing waste and minimizing environmental impact.

- Corrosion Resistance: Magnesium alloys, including AZ91D, exhibit good corrosion resistance. This makes them suitable for applications exposed to harsh environmental conditions, ensuring the longevity and durability of the cast components.

- Dimensional Stability: Magnesium alloys provide greater dimensional stability, making them a preferred choice for components where maintaining precise dimensions is critical. This is particularly beneficial in applications with stringent tolerance requirements.

Understanding and leveraging these unique properties, GEMS Manufacturing stands poised to deliver tailored solutions, ensuring that your magnesium die casting project not only meets but exceeds performance expectations.

Benefits of Choosing Magnesium for your Die Casting Project

Magnesium is stronger and stiffer than even the most advanced engineered plastics. It also provides greater wear resistance, higher temperature resistance, and better energy absorption/impact resistance characteristics. Magnesium provides greater corrosion resistance, and is better suited to large, thin-wall, net shape complex parts.

Compared to steel, magnesium is 75% lighter with no significant loss of strength. Compared to aluminum, magnesium is 33% lighter, with similar or improved mechanical properties, and machines easier. It is a far better material for complex, thin-walled, net shape or near-net shape castings and offers greater dimensional stability.

Magnesium castings can meet tight tolerances that would be difficult or impossible to achieve with steel. Tooling costs can be lower for magnesium castings, as multiple parts can be easily consolidated into a single component. This also improves component rigidity and reduces welding and assembly costs.

| Magnesium Die Casting | Primary Benefit of Mg | Secondary Benefit of Mg |

| vs. Steel Weldment | 75% Lighter | Less Expensive |

| vs. Aluminum Die Casting | 33% Lighter | Longer Tool Life |

| vs. Plastic Molding | Stronger, stiffer | Environmentally Stable |

Engage with GEMS Manufacturing for full product realization or at any point in the process about your Magnesium Die Casting project. You’ll always get our best thinking, along with the flexibility, agility and global supply chain expertise to take your product from idea to real-world impact.