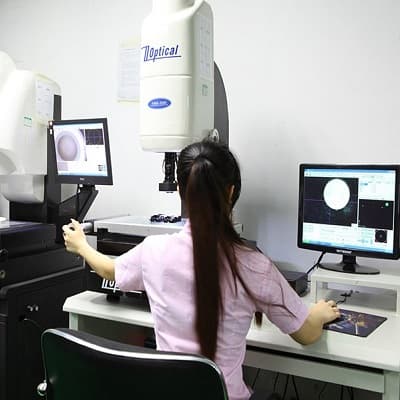

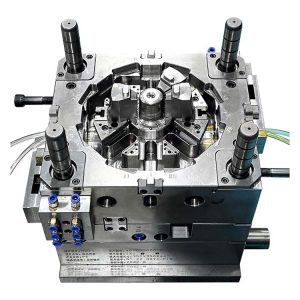

Mold making is a core manufacturing competency at GEMS-MFG, while we would like to highlight that there are NO product with our own brand. All of the products we supplied are custom made to the client’s specification, and in most case they need custom molds, molding or casting production, and sometimes secondary to generate the finished parts. To assure the best quality, our molds and parts are all precision fabricated using the best materials and the latest technologies. For a large percentage of our customers, they authorize us to make molds and continue the mass production at our facilities, and we also accept order to make exported molds for manufacturing abroad.

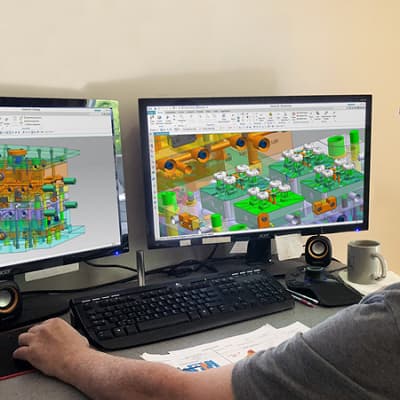

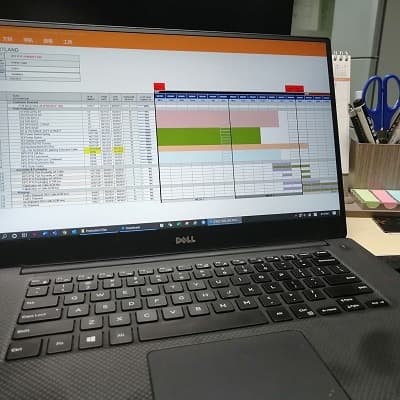

No matter what product applications requires, you can trust GEMS-MFG to do it, and more importantly we can make it better. You are free to make full use of our experienced design and engineering team, as well as our highly advanced technology and state-of-the-art equipment. Regarding to the project management, we will deliver superior outcomes while keeping you informed at each stage, as our team has a strong demand of professional consultation, careful attention to detail, and customized manufacturing solution services that are specifically tailored to your needs.

Our focus on accuracy in mold processing, along with our experience and expertise in manufacturing, gives you the advantage of producing precision inserts & components that are interchangeable to lower maintenance costs, longer mold life, and more reliable product quality.

CHINA TWO SHOT MOLD MANUFACTURER FOR 2K PLASTIC INJECTION MOLDING

CHINA TWO SHOT MOLD MANUFACTURER FOR 2K PLASTIC INJECTION MOLDING THERMOPLASTIC INJECTION MOLDING MOLD FOR VARIOUS APPLICATIONS

THERMOPLASTIC INJECTION MOLDING MOLD FOR VARIOUS APPLICATIONS HOME APPLIANCE ABS PP PLASTIC INJECTION MOLD

HOME APPLIANCE ABS PP PLASTIC INJECTION MOLD PLASTIC PARTS INJECTION INSERT AND OVERMOLDING MOLD

PLASTIC PARTS INJECTION INSERT AND OVERMOLDING MOLD MEDICAL PLASTIC TRANSPARENT PARTS INJECTION MOLD MANUFACUTRER

MEDICAL PLASTIC TRANSPARENT PARTS INJECTION MOLD MANUFACUTRER PROFESSIONAL AUTOMOTIVE PLASTIC INJECTION MOLD MAKING IN CHINA

PROFESSIONAL AUTOMOTIVE PLASTIC INJECTION MOLD MAKING IN CHINA