Navigating Design, Engineering, and Sustainability @GEMS-MFG

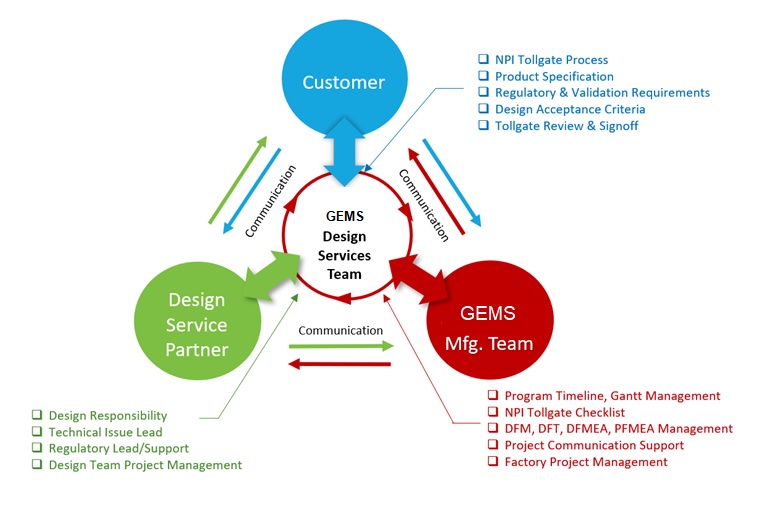

GEMS Manufacturing is a proactive partner to our customers. We develop and maintain close relationships, and we aim to be a crucial part of your success.

For maximum value, it is best to involve GEMS as early in your product development process as possible – ideally during the design stage. That way, we can anticipate the challenges and opportunities that lie ahead and help you to make efficient, sustainable decisions about material selection and product functionality, as well as manufacturing, assembly, decoration and logistics.

For the past years, GEMS has helped some of the world’s most respected companies take their products from the first seed of an idea all the way to a leader in the market. Our customers trust us because we do what we say—and we come through, even when others can’t.

1. Design For Manufacturability

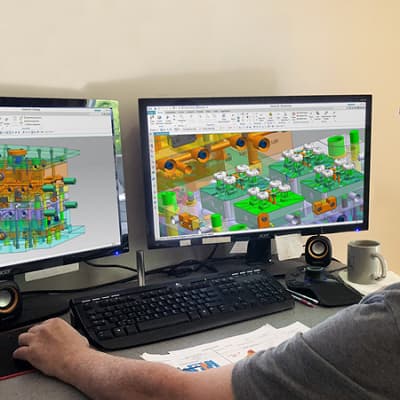

When you’re developing a highly complex product, you need a partner you can trust. When we partner with you to design a plastic part, metal component, cable, printed circuit board, electronic accessories, or complete assembly system, manufacturability is always critical. GEMS applies more than 20 years of manufacturing experience to the design for the manufacturability process. Our engineering and manufacturing teams work hand-in-hand to carry out a thorough reviewing process that looks at five principles: process, design, material, environment, and compliance testing. By analyzing risks and suggesting design changes when needed, we ensure that a component, sub-assemblies or complete product can be efficiently manufactured with no unnecessary costs during the product lifecycle. Design innovation can be the difference between a product that gets to market and one that defines the market. Our technical depth in design and engineering reduces overall product costs and enables you to launch competitively unique products.

2. Engineering In-Depth

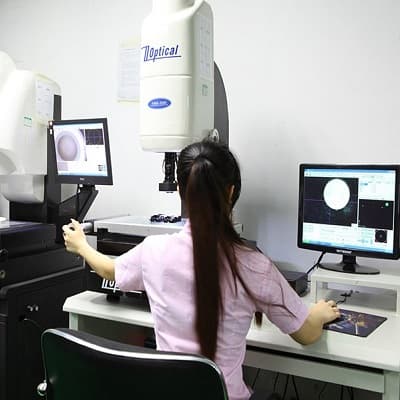

Our profound engineering expertise and experience in product development, test technology, assembly technology, and quality and reliability will assist you in reducing overall product cost and delivering high-quality goods. We understand and resolve the difficulties of unique projects with severe constraints and short schedules because we have a passion for engineering and a commitment to exceptional plastics and metals production and finished goods assembly. Whether you require individual components, pre-assembled parts, or ready-to-sell products, we are committed to developing better parts, methods and solutions.

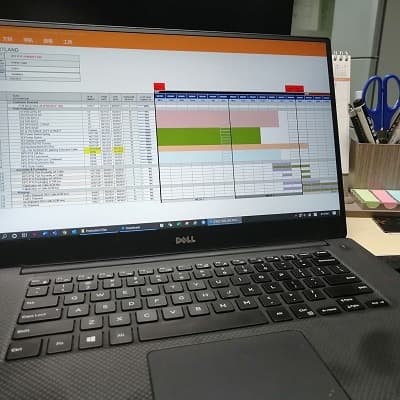

- Product Development: Early collaboration with GEMS can help you achieve higher quality and faster time-to-market while lowering your total cost of supply over the life of your products.

- Test Development: With our broad experience and expertise to what works in the manufacturing industry, we are able to provide test solutions that are tailored to your requirements. We analyze variables, weigh risks, and balance the costs of creating, producing, and deploying optimal, customized test solutions.

- Assembly Technology: We leverage our technical expertise to assist you in reducing time-to-market, developing cost-effective processes, and maintaining the best quality level. To make full use of our extensive knowledge and deep technical specialties, we can help address the whole product development lifecycle, from component material selection to qualification, test tool design and assembly, to improve and optimize processes.

3. Sustainability Integration

In an era where sustainability is paramount, GEMS Manufacturing is dedicated to integrating eco-friendly practices into every phase of the product development lifecycle. From material selection to manufacturing processes and packaging, we strive to minimize environmental impact without compromising product performance. Our commitment to sustainability goes beyond regulatory standards; we actively seek innovative solutions to reduce waste, energy consumption, and carbon footprint. Collaborate with us, and together we can create products that not only meet market demands but also contribute positively to the environment.

4. Continuous Improvement and Innovation

Embracing the dynamic nature of manufacturing, GEMS prioritizes continuous improvement and innovation. Our teams stay abreast of the latest technological advancements, industry trends, and best practices to ensure that your products benefit from cutting-edge solutions. Fostering a culture of innovation within our organization, we bring fresh perspectives and creative ideas to every project. Whether it’s adopting new materials, refining manufacturing processes, or enhancing product functionality, our commitment to continuous improvement positions your products at the forefront of the market.

5. Customer-Centric Approach

At the core of GEMS Manufacturing is a customer-centric philosophy. We understand that each client is unique, with specific needs and aspirations for their products. Our teams are dedicated to not only meeting but exceeding your expectations. We listen attentively to your requirements, provide transparent communication throughout the development process, and adapt our approach to align with your goals. Your success is our success, and our customer-centric approach ensures that we go above and beyond to deliver solutions that not only meet technical specifications but also resonate with your vision for the product.

Integrated Design, Engineering And Sustainability with GEMS Manufacturing

Our goal is to provide high-quality manufacturing solutions that will make your product more reliable, manufacturable, and marketable. GEMS’ design engineers are experts in plastic & metal parts and electro-mechanical assembly, and they can successfully translate client’s requirements into highly manufacturable product designs. GEMS assist customers like you in developing custom solutions that integrate seamlessly with the rest of your product design from concept to completion. We have the know-how to make your mechanical creations a reality. For producing specialized electro-mechanical assemblies, GEMS’ industrial, mechanical, electrical, and software engineering disciplines are tightly integrated. Regardless of how complex the project is, GEMS is eager to involve the new product development and offer a complete manufacturing solution.

We work as an extension of your own team. Performance, reliability, and cost are all maximized when components are developed, manufactured, and assembled as a unit by the same company. Working with one trustworthy partner to take care of the entire process ensures this result. GEMS Manufacturing is your one-stop solution provider for product development services. We can take your design from an early concept to a final gift box wrapped product with the exact quality specification you require, whether you’re launching a whole new product or fine-tuning an existing one. Our focus is to thoroughly understand your expectations, from the complexity of sourcing, to technical engineering, to the cost demands of your industry.

In summary, GEMS Manufacturing’s holistic approach to design and engineering encompasses Design for Manufacturability, Engineering In-Depth, Sustainability Integration, Continuous Improvement and Innovation, and a Customer-Centric Approach. This comprehensive suite of services positions us as a versatile and reliable partner for all your product development needs, ensuring not just quality and efficiency but also sustainability, innovation, and customer satisfaction.