Plastic Mold Making

Injection molds, or molding tool, are the formed halves that come together in the injection molding machine to be filled with molten plastic and produce the plastic parts in their image. The cavity side, or “Movable” side, is typically the half which will form the “best” surface of the part, and the core side, or “Fixed” side, will typically show the visual imperfections caused by ejector pins because the parts get ejected from this half.

Additional complexity can be added to injection molds in order to produce more complex plastic parts. To accommodate part features such as undercuts, molds can be augmented with side-pull mechanisms called slider. Slider moves into a cavity in a perpendicular direction from the draw of the mold halves to form the undercut feature, then stationary angle pins on the stationary mold half pull the slides away when the mold is opened. The pins enter a slot in the slides, and cause them to move backward when the moving half of the mold opens, like a cam. Then the part is ejected, the mold closes, and the slides move forward along the angle pins as a result of the closing action of the mold.

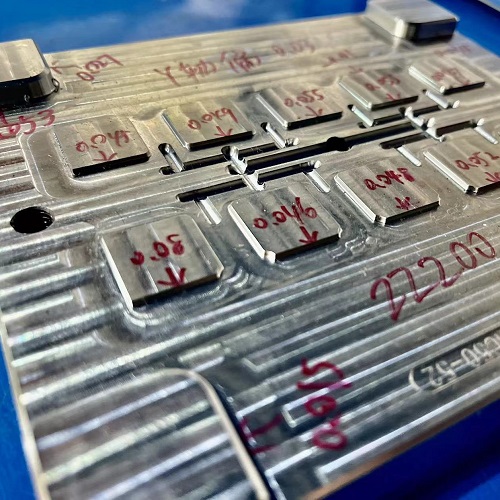

Injection molds are usually constructed from hardened steel or pre-hardened steel. The choice of mold material is determined by the number of parts to be produced. In general, hardened steel molds cost more to construct, but their longer lifespan will offset the higher initial cost over a higher number of parts made before wearing out. Pre-hardened steel molds are less wear-resistant and are used for lower volume requirements or larger components; their typical steel hardness is 38–45 on the Rockwell-C scale. Hardened steel molds are heat treated after machining; these are by far superior in terms of wear resistance and lifespan. Typical hardness ranges between 50 and 60 Rockwell-C (HRC). The molds can be manufactured by the combination of CNC machining, EDM sinking, Wire cutting, Polishing, Mold fitting & assembly processes.

With decades of mold making experience, GEMS understands a broad and relevant Steel and Resin portfolio in the material properties and appliances industries, and owns unparalleled expertise in helping customers achieve greater design flexibility and enhanced product specifications. GEMS is at the forefront of the manufacturing industry, providing innovative parts & products which help customers set their brands apart in these ultra-competitive markets.