End-to-End Partnership Solutions

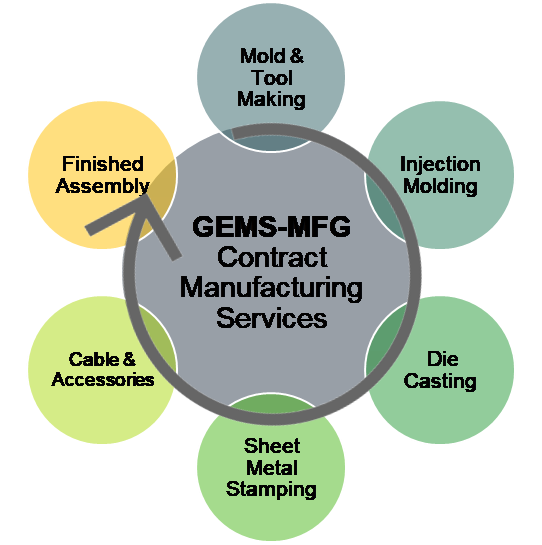

Whether you are looking to introduce new products to the market, upgrade legacy products, achieve cost requirements, or meet regulatory requirements, GEMS is ready. Our network of manufacturing facilities is strategically located, allowing us to develop intimate relationships with our customers and work closely with you to solve complex challenges. We have an extensive suite of integrated manufacturing capabilities, allowing for full system integration of complex assemblies and modules. We also leverage our supply chain to manage materials and components, bringing products to market faster and more cost-effectively.

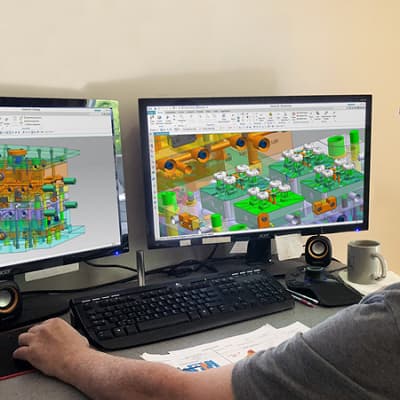

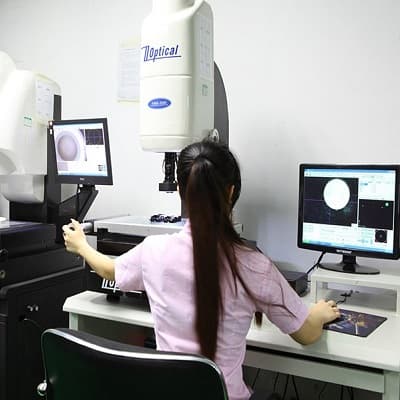

Every customer has specialized manufacturing needs. We have facilities in each major manufacturing region with appropriate industry-specific quality certifications and a team experienced in complete end-to-end partnership solutions and lifecycle support. We design customer solutions to solve your complex engineering and manufacturing challenges. Our commitment to our client‘s success has seen us evolve into a Metals, Plastics and Electronics Manufacturing Solutions & Electro-mechanical Assemblies Integration Services provider. From design to prototyping, mass production and field service we support our clients through the complete lifecycle. When you partner with us, we assemble a custom solutions team of experts for you, drawing from our technology, engineering, and manufacturing business units. Through this integrated process, you receive best-in-class expertise in multiple technologies from one flexible supplier.