2K Plastic Injection Molding Services in China

2K Molding is well known as 2 shot injection molding or two-colour injection moulding, consists of two different plastics or two different colors of one plastics into an end product by means of one injection molding process. 2K injection moulding perform in one machine which is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The 2k plastic injection moulding is then rotated automatically and another type of plastic is injected from a second nozzle into the mold.

GEMS Manufacturing is a professional contract manufacturing provider that has manufactured parts using the 2K injection moulding process for more than 20 years. The 2k injection molding process enables several functions to be integrated into an injection molded part. Due to the chemical bond between the different materials, excellent adhesion is achieved, without the thermoplastic part requiring chemical pre-treatment. Two colours / 2K injection moulding component technology is also ideal for parts with large batches. The 2k injection moulding allows us to integrate multiple properties into one product: for instance, layered products, combinations of hard and soft plastic for making different color combinations.

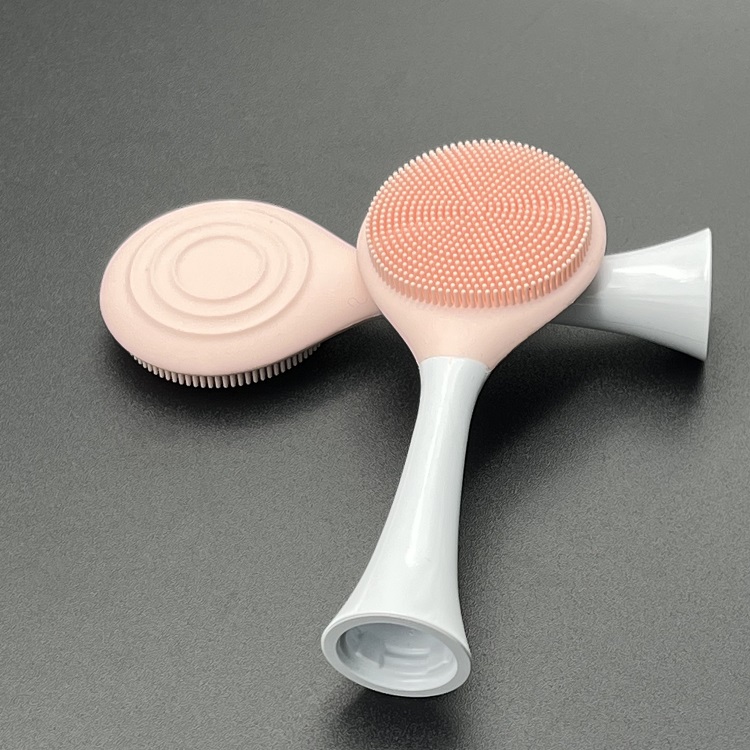

Almost all industries can use two colour injection moulding for a variety of product designs. The 2k injection also allows for moulding using clear plastics, colored graphics, and stylish finishes which improves customer’s product functionality and marketplace value. We also use this method for items made from a single material, but with multiple colours, shades or transparencies. This can be useful for making objects with viewing windows, or for making multi-coloured items without painting. Multi-K moulding streamlines the process by removing the post-production stage. The opportunities are practically endless, with skill and imagination.

Understanding The Basics of 2K Plastic Injection Molding

- 2K Molding Defined: GEMS-MFG specializes in 2K plastic injection molding, often referred to as two-shot molding or dual-shot molding. This involves injecting two different materials into a single mold to create a complex, multi-material plastic component. GEMS-MFG excels in seamlessly integrating materials with distinct properties or colors within a single part, eliminating the need for secondary assembly processes.

- Materials Involved: The two materials used in GEMS-MFG’s 2K molding processes can vary in terms of composition, hardness, or color. Common combinations include a rigid material combined with a flexible one, or the integration of materials with different colors for aesthetic or functional purposes.

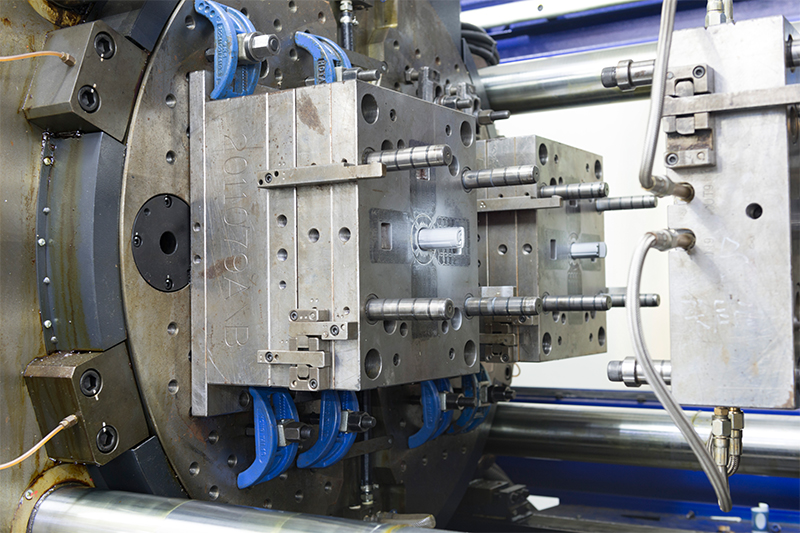

- Machinery and Technology: GEMS-MFG employs specialized injection molding machines equipped with multiple barrels and injection units for precise control over the injection sequence. This ensures accurate placement of each material within the mold. The company’s process involves meticulous attention to material compatibility, viscosity, and shrinkage rates to achieve optimal part quality.

The Advantages of 2K Molding

- Design Flexibility: GEMS-MFG stands out for offering unparalleled design flexibility. Manufacturers partnering with ABC can create complex parts with varying material properties in a single manufacturing cycle, leading to enhanced functionality and aesthetic appeal.

- Reduced Assembly Costs: By integrating multiple materials within a single part, GEMS-MFG’s 2K molding eliminates the need for additional assembly processes. This streamlines production, reduces labor costs, and minimizes the risk of errors associated with manual assembly.

- Enhanced Product Durability: GEMS-MFG’s expertise in combining materials with different properties allows for the creation of components with improved durability and performance. For instance, a rigid material can be strategically combined with a flexible one to achieve optimal strength and resilience.

Advantages Of 2K Injection Molding

- Advanced Technologies

As a global manufacturing hub, China has become a frontrunner in adopting and advancing 2K plastic injection molding technologies, and GEMS-MFG has been at the forefront of this progress. The company boasts a robust infrastructure of manufacturing facilities equipped with state-of-the-art machinery designed for precision and efficiency in 2K molding processes.

- High-Precision Machinery:

GEMS-MFG’s commitment to excellence is evident in its use of high-precision injection molding machines specifically designed for 2K molding applications. These machines feature advanced control systems that ensure accurate placement of materials, leading to consistent and high-quality parts.

- Expertise in Mold Design:

The success of GEMS-MFG in the 2K molding arena hinges on meticulous mold design. The company exhibits expertise in designing molds that accommodate the complexities of multi-material injection. This includes considerations for material compatibility, flow paths, and cooling systems to achieve optimal results.

- Material Selection and Compatibility:

A key aspect of GEMS-MFG’s prowess in 2K molding lies in its thorough understanding of material properties and compatibility. The company carefully selects materials that complement each other, considering factors such as adhesion, shrinkage, and thermal characteristics.

- Strategic Approach:

GEMS-MFG’s approach to 2K plastic injection molding is marked by a strategic and comprehensive methodology. The company recognizes the diverse needs of industries and tailors its processes to deliver solutions that align with these requirements.

- Industry Diversification:

GEMS-MFG caters to a wide range of industries, including automotive, electronics, medical devices, and consumer goods. This diversification allows the company to accumulate extensive experience and adapt its 2K molding services to suit the specific needs of different sectors.

- Strategic Material Pairing:

The strategic pairing of materials in GEMS-MFG’s 2K molding is a distinguishing feature. The company carefully selects material combinations to meet the mechanical, thermal, and aesthetic demands of the intended application.

- Quality Control Measures:

GEMS-MFG places a strong emphasis on quality control throughout the 2K molding process. Rigorous testing and inspection protocols are implemented to ensure that each part meets the required standards for dimensional accuracy, material adhesion, and overall performance.

Applications of 2K Plastic Injection Molding by GEMS-MFG

- Automotive Industry

In the automotive sector, GEMS-MFG’s expertise in 2K plastic injection molding, including Dual-Shot Molding and 2-Shot Injection Molding, has become instrumental. The company produces complex components that contribute to vehicle aesthetics, functionality, and safety. Examples include integrated handles, buttons, and interior trims that seamlessly combine different materials for ergonomic design and enhanced user experience.

- Electronics and Consumer Goods

The electronics industry benefits significantly from GEMS-MFG’s advanced molding techniques for the production of intricate parts such as keypad buttons, casings with embedded gaskets, and wear-resistant surfaces. In consumer goods, GEMS-MFG’s technology is employed to create visually appealing and durable products, such as multi-colored housings for electronic devices.

- Medical Devices

The medical industry leverages GEMS-MFG’s 2K plastic injection molding, including Dual-Shot Molding and 2-Shot Injection Molding, to manufacture components with specialized material combinations. This includes medical device housings with integrated seals, ergonomic grips, and components requiring a combination of rigid and soft materials for patient comfort and safety.

- Future Trends and Innovations

As technology continues to evolve, the landscape of 2K plastic injection molding, including Dual-Shot Molding and 2-Shot Injection Molding, is poised for further advancements. Future trends in this field may include:

- Increased Material Compatibility: GEMS-MFG remains at the forefront of research and development efforts, aiming to expand the range of materials compatible with 2K molding. This provides manufacturers with even greater flexibility in material selection.

- Enhanced Automation: GEMS-MFG anticipates advancements in automation technology, leading to increased automation in 2K molding processes. This would improve efficiency, reduce production costs, and minimize human error.

- Intelligent Molding Solutions: The integration of smart technologies, such as sensors and real-time monitoring systems, by GEMS-MFG could enhance the precision and quality control measures in 2K plastic injection molding.

- Customization and Personalization: With growing demand for customized products, GEMS-MFG envisions more extensive customization options in the future, allowing manufacturers to tailor multi-material components to specific client requirements.

Conclusion

In conclusion, GEMS-MFG’s introduction of 2K plastic injection molding services in China, including Dual-Shot Molding and 2-Shot Injection Molding, marks a significant advancement in the field of plastic manufacturing. This innovative company, characterized by its ability to seamlessly integrate multiple materials within a single part, has found widespread applications across diverse industries. GEMS-MFG’s strategic approach, leveraging advanced technologies, meticulous mold design, and a comprehensive understanding of material properties, positions it as a leader in providing 2K molding solutions.

As the demand for complex, multi-material components continues to grow, GEMS-MFG’s expertise in 2K plastic injection molding, including Dual-Shot Molding and 2-Shot Injection Molding, is poised to play a pivotal role in shaping the future of manufacturing. The synergistic combination of technological expertise, strategic methodologies, and a commitment to quality positions GEMS-MFG as a key player in delivering cutting-edge 2K plastic injection molding services that meet the evolving needs of industries worldwide.