Turnkey manufacturing solution is a process that one company manages every aspect of a project’s production from sart to finish. They are in charge of all project phases, beginning with the initial design phase and proceeding through tooling, machining, quality assurance, and then assembling, packaging, and eventually shipping. In the highly globalized and competitive manufacturing market, there is a constant need to increase performance and deliver on time in order to assure the company’s growth. Turnkey manufacturing services are an excellent option for your next equipment procurement project.

Turnkey manufacturing solution is a process that one company manages every aspect of a project’s production from sart to finish. They are in charge of all project phases, beginning with the initial design phase and proceeding through tooling, machining, quality assurance, and then assembling, packaging, and eventually shipping. In the highly globalized and competitive manufacturing market, there is a constant need to increase performance and deliver on time in order to assure the company’s growth. Turnkey manufacturing services are an excellent option for your next equipment procurement project.

Numerous Benefits To Maintain Production From Turnkey Manufacturing Solution

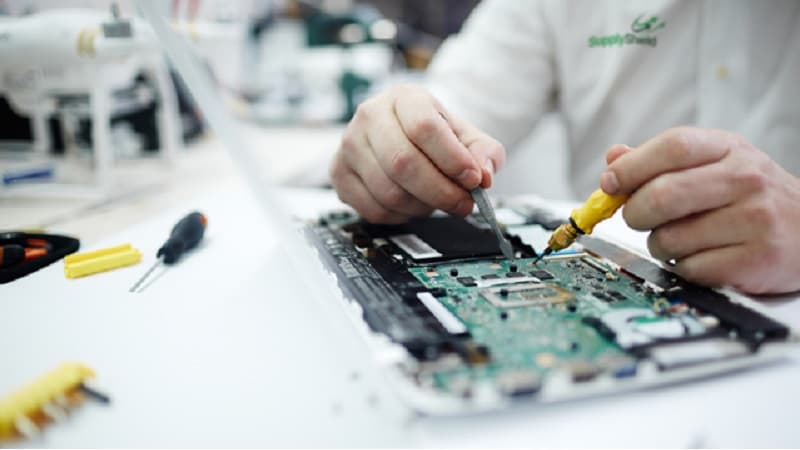

There are numerous benefits to maintaining most or all stages of turnkey production with manufacturing solution like GEMS-MFG, including improved communication and cost reductions. We’ll go through each of these benefits in depth further down.

1. Cost Reduction

Working with GEMS manufacturing, in its most basic form, allows a client to produce its goods without incurring significant overhead. Once a company has a finished prototype, all it has to do now is to connect with GEMS Manufacturing to make the items or components that they will assemble. For a company that makes products including metal, plastic and electronic components, it represents tens, if not hundreds of thousands of dollars in startup costs and ongoing overhead. Things like raw materials, fabrication facilities such as CNC machines and die casting equipment, labor, and machine maintenance are all major barriers to entry for a small company.

2. Improved Lead Time

When a corporation engages with GEMS Manufacturing to supplement their own production line with only specified parts or assemblies, they can save their own manufacturing time. Taking advantage of the manufacturer’s technical expertise is one critical advantage that you can enjoy when working with GEMS Manufacturing. When sourcing a new product, for example, we will be able to advise you on the best materials, processes and applications. As a result, there is a faster time to market, better delivery times, and better customer service.

3. Consistent High Quality

Companies can maintain constant production of high-quality products with the help of GEMS Manufacturing. You can make full use of our quality control processes in addition to the technical expertise. Typically, GEMS Manufacturing will take responsibility for inspecting your products and replacing any that are defective. This process would not only be time-consuming for internal work-forces, but also be financially accountable for the wasted materials. Setting that top quality level will help client to boost brand awareness and establish a reputation as a trustworthy distributor.

4. Scalability Opportunities

When a firm considers expanding its manufacturing operations, it is common for them to look for overseas partners like China where typically factories can make items in considerably bigger volumes and at a lower cost. When your organization works with GEMS Manufacturing who already has worldwide connections, you won’t have to worry about language barriers and expensive overseas trips. You can save yourself months, if not years of vetting and relationship building by leveraging our existing manufacturing resources and relationships.

5. Resource Prioritization

All of the money and resources saved through GEMS Manufacturing can be allocated to other areas of the business. For example, using the saved capital a client could improve its marketing methods, hire additional staff for other departments, and/or boost sales efforts. When we handle the product manufacturing, a customer may concentrate on its core values and strengths.

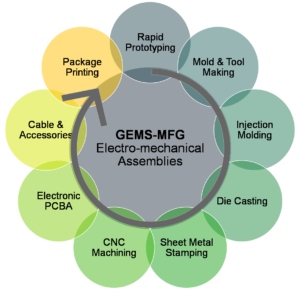

ONE-STOP Turkey Manufacturing Solutions @GEMS-MFG

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

GEMS-MFG, based in Shenzhen, China, has been providing Manufacturing Solutions for Plastics, Metal and Electronic Part and Electro-mechanical Assembly Integration Services to USA, UK, EURO and other oversea markets. As explained above, current supply chain issues have highlighted the need for more reliable ONE-STOP manufacturer like GEMS Manufacturing, who you can trust to support your business like your own eyes and hands in China when you are inconvenient to travel.

To learn more about how GEMS Manufacturing can help resolve your supply chain challenges, contact us or request a quote today.