The global digital economy generates a variety of internal and external obstacles that make New Product Introduction (NPI) more difficult. As everything becomes digital, from vehicles to light bulbs, products are becoming more and more complicated, life cycles are becoming shorter, technology is evolving faster, margins are shrinking, and the demand for electronic components is increasing. Furthermore, the changing market conditions, such as trade agreements, tariffs and geopolitical crises, are added to the list of unpredictability factors for NPI that leads to uncontrolled manufacturing timelines.

The global digital economy generates a variety of internal and external obstacles that make New Product Introduction (NPI) more difficult. As everything becomes digital, from vehicles to light bulbs, products are becoming more and more complicated, life cycles are becoming shorter, technology is evolving faster, margins are shrinking, and the demand for electronic components is increasing. Furthermore, the changing market conditions, such as trade agreements, tariffs and geopolitical crises, are added to the list of unpredictability factors for NPI that leads to uncontrolled manufacturing timelines.

Critical Aspects To be Improved For The NPI’s Manufacturing Timelines

To combat this uncertainty, companies are looking inward to implement near-term operational improvements as one of the actions to boost revenue growth. However, we found a sector that has yet to be modernized but has enormous potential to boost corporate performance is New Product Introduction (NPI), and here are certain static solutions to improve the manufacturing timelines under such dynamic conditions.

1. Follow a disciplined and well-planned NPI process

When it comes to the introduction of new products, manufacturers or OEMs need detailed information, time and dedicated resources from an organization. Companies who successfully create and launch new or upgraded products always follow a disciplined and well-planned process on a regular basis — so called the New Product Introduction (NPI) process, which assists in bringing all the right resources together at the right time. Typically it consists of six phases below: Define; Feasibility; Develop; Validate; Implement; Evaluate. The NPI process is not a straight line, instead each phase of the NPI process may feed into the next.

2. Keep using productive tools to meet with today’s dynamic conditions

Technology has raised the stakes and increased the difficulty of launching a successful product, although good news is that new techniques have lowered the bar for product development, allowing companies and start-ups to launch more products into market faster and cheaper. With a demand for shorter product life cycles and greater product variety, New Product Development (NPD) teams are under constant pressure to create a diverse portfolio of new product options, so it is critical to use the most up-to-date tools to meet with today’s dynamic conditions. For example, for the design and engineering phases of product development, productive tools like 3D CAD, virtual reality, design for manufacturing (DFM), industrial internet of things (IIoT), and generative design are recommended that firms can use to explore, model, and refine product concepts.

3. Collaborate with the manufacturing partners with strong practices

Bringing a successful product into market is definitely a team-effort. NPI is a comprehensive cross-functional practice that is represented by design, manufacturing, quality, marketing, and packaging, as well as customer service, regulatory and sourcing divisions. In a digitally-driven world, companies always focus on promoting the sales with brand new design product, innovative business models and marketing channels. Despite this, the importance of solid experience and technical expertise that goes into the manufacturing is often overlooked or underestimated. It is time to extend the focus onto the collaboration with the manufacturing partners with strong practices. Operation team is assumed to weigh all of the risks, expenses and trade-offs to select the right suppliers at the right locations with the right supply.

4. Early integration of NPI to set the right expectation

In addition to collaborate with the right manufacturer, early integration of related parties will help organizations navigate the changing market conditions. Pre-mortem planning highlights potential issues so that the unexpected can be anticipated and minimized. By incorporating the Voice of Manufacturers (VOM) in the early stages of the project, the product design team can avoid late design changes, multiple revisions and costly validation testing. Target-based costing, which identifies the intended profit margin and the maximum permissible cost to fulfill that margin, allows all team members to understand pricing targets and key budget drivers ahead of time, so they can be considered in every phase of NPI, from design to delivery. Finally, incorporating manufacturing early in the process allows for earlier supply trade-offs.

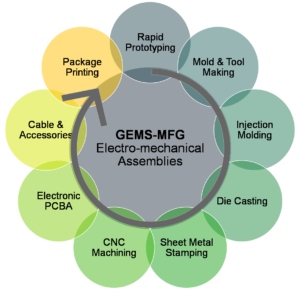

SOLID Experience & Expertise for NPI @GEMS-MFG

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

GEMS-MFG, based in Shenzhen, China, has been providing Manufacturing Solutions for Plastics, Metal and Electronic Part and Electro-mechanical Assembly Integration Services to USA, UK, EURO and other oversea markets. Current supply chain issues have highlighted the need for more reliable ONE-STOP manufacturer like GEMS Manufacturing, who you can trust to support your business like your own eyes and hands in China when you are inconvenient to travel.

To learn more about how GEMS Manufacturing can help improve your manufacturing timelines for New Product Introduction (NPI) and resolve your supply chain challenges, contact us or request a quote today.