Since the start of the COVID-19 epidemic, the supply chain has experienced productivity challenges, labor shortages, raw material shortages, and scheduling delays, affecting practically every industry. Manufacturing enterprises have been struck particularly severely, along with restaurants, department stores, and other consumer-facing businesses. The question remains as to whether the international business community will be able to reclaim control of the supply chain and increase productivity.

Since the start of the COVID-19 epidemic, the supply chain has experienced productivity challenges, labor shortages, raw material shortages, and scheduling delays, affecting practically every industry. Manufacturing enterprises have been struck particularly severely, along with restaurants, department stores, and other consumer-facing businesses. The question remains as to whether the international business community will be able to reclaim control of the supply chain and increase productivity.

How to Deal with Today’s Supply Chain Problems

As you can see, the pandemic has posed some unique supply chain problems, which eCommerce merchants are still dealing with on a daily basis. The good news is that there are a slew of options for resolving big concerns and avoiding inventory shortages in the future, although there is no one-size-fits-all strategy to supply chain planning, a combination of a few strategies may yield the most full and thorough results.

1. Maintain your company’s cash liquidity.

Protect your company by obtaining financing on a flexible basis. Having cash on hand, after all, can mean the difference between meeting demand and running out of product. With sharp inventory ebbs and flows expected in the coming months, it’s a good idea to explore a flexible line of credit that may be utilized to stock up on evergreen or perennial high-demand commodities and pay for priority manufacturing/shipping, or even air freighting.

2. Diversify your sourcing sources for commodities.

Increase your supply chain’s choice and abundance by expanding your sourcing options, possibly geographically. It’s easier to become more flexible and adapt to a continuously changing market by cultivating a lot of supplier connections (i.e. during a prolonged pandemic that alters the entire global economy). Diverse sourcing is often the key to a brand’s success, as it allows them to quickly locate goods and materials while maintaining revenues, expanding their consumer base, and increasing innovation.

3. Partner with a freight forwarder.

To oversee and track the shipment of your goods, work with a freight forwarder — or many. While freight forwarding businesses are responsible for moving goods from one location to another, they can also help shippers organize the entire process and negotiate the best pricing and/or fastest route. A freight forwarder’s enormous understanding of the supply chain, as well as their capacity to address unforeseen problems in real time, it benefit retailers who work with them (such as delayed goods or rerouted services). Furthermore, by combining the shipments of smaller retailers, freight forwarders are able to negotiate at scale.

4. Identify alternative ports for importing.

Regardless of unanticipated events or a sudden rise in customer orders, hedge your risks by finding out other ports to meet your fulfillment demands and stay on schedule. The sister ports of Los Angeles and Long Beach have become the cornerstone of Transpacific trade as DTC brands become increasingly reliant on Asian imports. Given that these ports handle nearly 25% of North America’s ocean freight, having a backup plan is wise and necessary in case of congestion or other inefficiencies.

5. Improve the forecast of demand.

Using automations to calculate the KPIs on your behalf is, without a doubt, the best method to improve forecasting of demand. To avoid stockouts or inventory shortages, e-Commerce sellers strive to find a balance among their inventory levels, warehousing expenses, and client demand. Merchants can stock up with confidence basing on projected product demand and/or sales thanks to automatic inventory notifications, forecasting tools, and cash on hand. Furthermore, prioritizing forecasts can help to streamline inventory counts and cut down on unnecessary overhead costs.

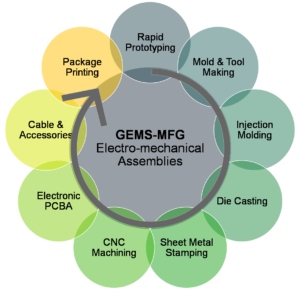

EXCELLENCE In Supply Chain Practices @GEMS-MFG

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

GEMS-MFG, based in Shenzhen, China, has been providing Manufacturing Solutions for Plastics, Metal and Electronic Part and Electro-mechanical Assembly Integration Services to USA, UK, EURO and other oversea markets. As explained above, current supply chain issues have highlighted the need for more reliable ONE-STOP manufacturer like GEMS Manufacturing, who you can trust to support your business like your own eyes and hands in China when you are inconvenient to travel.

To learn more about how GEMS Manufacturing can help resolve your supply chain challenges, contact us or request a quote today.