A question I am frequently asked is, what does it take to be a successful Project Manager? It’s as if there’s a secret formula for project management success. Some say that only experience counts, while others favor formal training and certifications. The ideal answer might be to have a mix of real-world experience and training, as the reality is that one can’t manage the project flawlessly but very often run across a series of challenges and obstacles before reaching success.

But still, what does it take to be distinguished in project management? Why do some people get into the groove right away, while others struggle and gasp for air? Though there are many skills, knowledge areas, approaches, and other factors to consider, let’s explore 5 key qualities that lead to project management success and create a business environment of trust, communication, and productivity.

1. Communicate Effectively

Clear and effective communication has always stood at the forefront of a successful project. However, in an age when communication channels are ever so abundant, a conversation between colleagues has become anything but clear and productive. If your communication lacks of order and organization, it will have a negative effect on a business that’s even worse than miscommunication itself.

Many teams get distracted by tools and virtual technology that they neglect about face-to-face collaboration. It is critical to ensure that project meetings are arranged on a regular and ad hoc basis. Assist the team in determining their preferred method of communicating and asking questions about their tasks. Weekly project meeting on Monday is a great way to recap the team’s actions and assure all members are updated on the same page, and start the new week off in a productive manner.

2. Manage Workflow, not People

Most project managers easily fall into in the futile practice of micromanagement. A team with a distrustful project manager has little chance of succeeding, while a team with one PM who can take responsibility without being control-obsessed, on the other hand, is in much better hands. Excessively controlling and relocating the team (or worse, blaming them for shortcomings) is never a solution for a great project manager. On the contrary, to hire the right individuals for the proper jobs and to offer coaching, training, and personal development are the keys to dissolve micromanagement. The project managers trust and appreciate their teams’ abilities, and they concentrate on addressing bottlenecks and reducing delivery timelines.

A good project manager also understands that project success is built on the efficiency of workflow. Creating a seamless workflow without delays and impediments is one of his top priorities to hit task goal. To accomplish so, barriers and bottlenecks must be avoided early on, and conflicts must be resolved with care and without delay. The Kanban Method is a set of practices that project managers can use to accomplish all of the above. It’s an approach that opposes the idea of utilizing every minute of your team’s time. Rather, it focuses on balancing demand and capacity to achieve optimum workflow efficiency.

3. Make Data-Base Decisions

While working on the details and specifics, a competent project manager should be able to keep the big picture of whole project in mind. When difficulties happen, he will be able to tackle them more quickly, as he is aware of the issues sooner and better prepared. To properly resolve a problem, first conduct with thorough research compiling a list of at least three alternative solutions, and then make the decision to the best course of action.

Decisions are made by project managers, and they’re usually evaluated by the amount of right decisions they make. How can they maximize this amount? The most convinced way to back one’s decision with a valid argument is to have data behind actions. Most companies own such data, but they don’t know how to use it and seldomly leverage its power. Kanban is one practical tool for project manager to use and keep track of delivery times, identify bottlenecks quickly, and rely on high-probability estimates.

4. Team Engagement and Motivation

Your project’s success is determined by your project team. We may not always have a choice in deciding who joins our team, but we do have a say in how we manage, grow and get the most out of them. Building high-performing teams is often ignored as key strength for a project manager, which seems surprised, considering how critical your team is to the projects and to you as project manager. It is well deserved for the time and effort you put into engaging and motivating your team to execute in top performance.

How can you lead a project team to execute at a high level by motivating and engaging them? Give them a clear picture of the expected outcome and they’ll be able to empower themselves to find their own path to success. Engage them in a conversation and care about their feelings about the project, their role, the charter, and so on. Show them where their contribution matters. Listen to them, cheerlead for them, challenge them, and build trust.

5. Set Realistic Expectation and Say “NO”

It’s an art to managing the expectations from consumer and stakeholder. A good project manager is suppose to fully understand the team’s capabilities and capacities that he or she can consider before signing the contract and say NO if necessary. Even after a project is kicked off, client requests and changes are continually flowing in a rapid iteration market. The project manager, however, realizes it is imperative to say NO to customers sometimes when far beyond established boundaries or prescribed limits, in a respectful but firm manner.

Putting the well-being of your team and managing realistic expectations is a crucial project management approach. This way, great project managers protect their team from burnout, their workflow from getting stuck, and their project from unavoidable and expensive delays.

READY For Your Next Project Management @GEMS-MFG

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

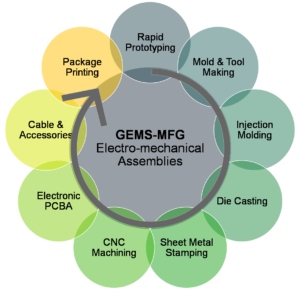

GEMS-MFG, based in Shenzhen, China, has been providing Manufacturing Solutions for Plastics, Metal and Electronic Part and Electro-mechanical Assembly Integration Services to USA, UK, EURO and other oversea markets. Current supply chain issues have highlighted the need for more reliable ONE-STOP manufacturer like GEMS Manufacturing, who you can trust to support your business like your own eyes and hands in China when you are inconvenient to travel.

To learn more about how GEMS Manufacturing can help improve your manufacturing timelines for New Product Introduction (NPI) and resolve your supply chain challenges, contact us or request a quote today.