Electronic PCBA Manufacturing in Shenzhen, China

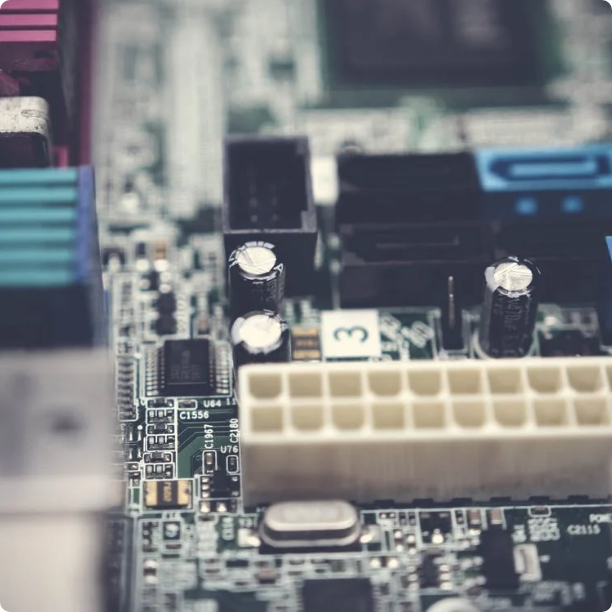

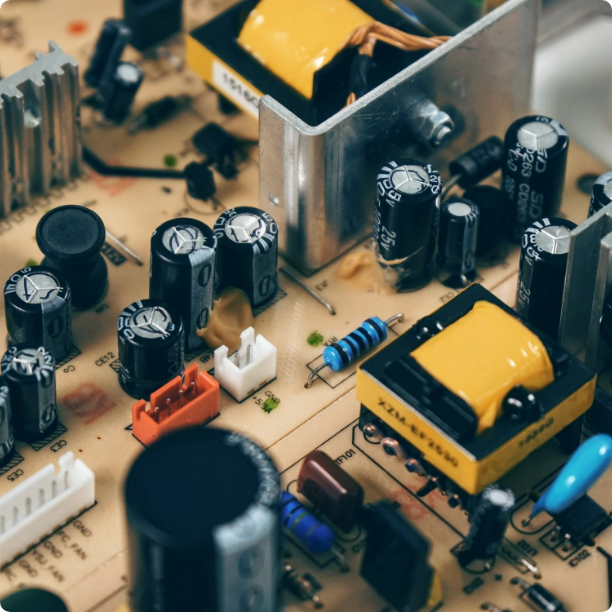

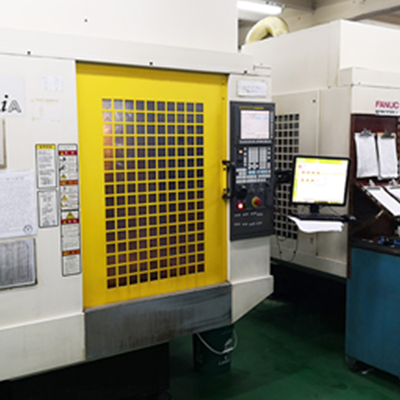

— As the buying power of consumer’s growth, they spent more on personal care and home appliance products. Many of these goods require unique intelligent functionality with built-in PCBA to manage the performance, also to keep products safe for application and light-weight for transportation. GEMS engages with value chain partners in the electronics PCBA industry to address these challenges through collaborations with verified manufacturing factories through our engineering innovation out of production. With unparalleled precision, all PCBs assembled by GEMS are carefully monitored using the latest automated Surface Mount Technology (SMT) assembly and inspection technologies.

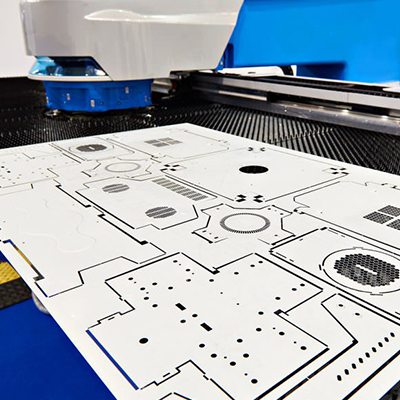

Printed circuit board assembly (PCBA) is becoming one of our core services. From multi-layered to flexible printed circuit boards, GEMS is your one-stop shop for printed circuit board assembly, testing, and commodity sourcing of boards and other material services. Our manufacturing facilities are fully equipped with state-of-the-art testing and verification equipment. Finished PCB Assemblies are checked for proper component placement and functionality with a variety of methods including AOI Inspection, In-Circuit testing, and X-Ray inspection. Once a PCBA is fitted with all necessary components and passed through the SMT assembly line, it is verified for compliance with customer CAD data using an inline AOI machine. Boards with bottom terminated components will go through x-ray inspection to ensure part-placement accuracy. Each assembly may then be subjected to in-circuit testing and/or functionally tested to customer specifications by a dedicated staff of test technicians. The functional test standard used in the above process can be as simple as a set of electronic measuring devices on a workbench or as complex as a six-foot, rack-mounted, integrated testing system. While many customers choose to use functional test fixtures, GEMS engineering staff have full capabilities to design and build such customized fixtures for quick and accurate testings.