Vaule Added Service: Custom Cable Manufacturing in Shenzhen, China

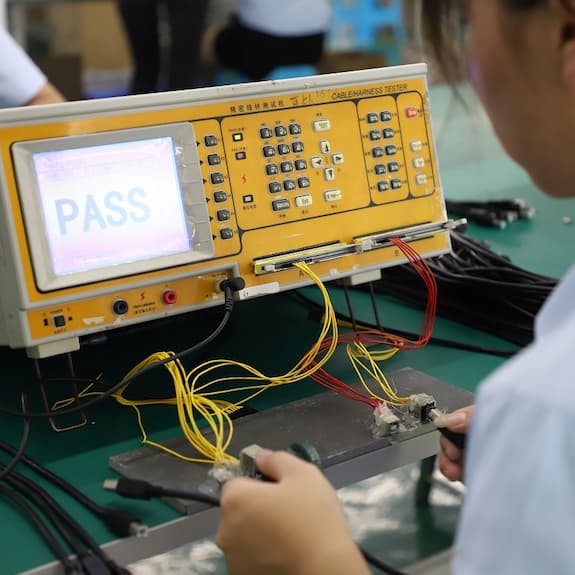

— GEMS is one of the best choices to be your CUSTOM CABLE manufacturing partner. We have the capabilities and manufacturing expertise to meet your exact needs. We can take your project from an engineered prototype to full production. We have the resources and experience to develop custom solutions at a superior value.

For custom cables like USB cable, Powered cable, Ethernet cable, Magnetic pogo pin cable, FPC ribbon Cable and others, we could help optimize your design and print your logo at the cable heads or specific areas. For ODM service, our professional engineer will give you the best price according to your drawing specification, and you may make full use of those PCBA, connectors and heads that we already developed the molds for unique requirements.