Die casting is the term used to describe the process of producing complicated metal components using molds, also known as dies or tools. The process uses non-ferrous metals that do not contain iron, such as aluminum, zinc, and magnesium, because they are featured with several metals’ desirable properties, such as reduced weight, increased conductivity, non-magnetic conductivity and corrosion resistance.

For GEMS Manufacturing, we focus on three primary alloys used as die casting material to choose from: zinc, aluminum and magnesium. Although each is an excellent metal to use, there are situations in which one metal is better than the others to get to the right finished product:

- Aluminum alloys: Best used in projects that require higher temperatures and are one of the longest-lasting materials on the market

- Zinc alloys: Allow more significant variation in section thickness and maintain closer tolerances, also better in impact strength and longest tool life

- Magnesium alloys: Lightest in weight with a good strength-to-weight ratio

To learn more details about the die casting alloys or the die casting process, please scroll down.

1. Aluminum Die Casting

The strength, corrosion resistance, and heat dispersing qualities of aluminum provide substantial benefits to mechanical designers. Aluminum castings are the lightest of all die cast alloys and can endure the highest operating temperatures. The aluminum is heated to liquid and then poured into the cavity using a pressure die casting machine with a die casting mold to produce aluminum die casting pieces with specific shapes and sizes.

Advantages of Aluminum Die Casting

- Lightweight and durable

- Great corrosion resistance

- High thermal and electrical conductivity

- Good strength and hardness

- High dimensional stability for complex shapes and thin walls

- Retains strength at high temperatures

- Less expensive

- High utilization rate of material

- A longer die life

- Does not require as much finishing work as magnesium

Aluminum Die Casting Applications

- Aluminum casting improves automotive fuel efficiency by contributing to weight saving.

- Aluminum is used in a broad range of networking and infrastructure equipment in the telecom and computing industries because RF filter boxes and housings require heat dissipation.

- In handheld devices, aluminum castings provide EMI/RFI shielding, rigidity, and durability with minimal weight.

- Because of aluminum’s excellent electrical performance and shielding properties, even in high-temperature environments, die cast aluminum is ideal for electronic connectors and housings

2. Magnesium Die Casting

There are numerous advantages to die cast magnesium components. Magnesium is the lightest of all structured materials, and it also possesses exceptional stiffness and strength-to-weight ratios. When comparing to Aluminum, Magnesium is softer, less stable and bends more easily under stress. Furthermore, it is more costly than aluminum. Magnesium has a greater melting point than zinc, which might increase the cost of casting.

Advantages of Magnesium Die Casting

- Excellent stiffness and strength-to-weight ratios

- High conductivity, electrical and thermal

- Withstand high operating temperatures

- High dimensional accuracy and stability

- Exceptional thin wall capability

- Good environmental corrosion resistance

- Good finishing characteristics

- Full recyclability

Magnesium Die Casting Applications

- Magnesium alloy is 30% lighter than aluminum alloy and 80% lighter than steel. Therefore, magnesium alloy has become an ideal material for parts manufacturing in portable mechanical products.

- Magnesium alloy has an excellent strength to weight ratio in metal and plastic engineering materials, and also has good electromagnetic wave barrier function, suitable for the production of electronic products.

- The minimum wall thickness of magnesium alloy castings can reach 0.6 mm, which cannot be achieved by plastics under the same strength. The die casting performance of aluminum alloy can be compared with that of magnesium alloy only when it is above 1.2-1.5mm.

- Magnesium die casting is used in a variability of automobile components because Magnesium has excellent shock absorption performance, which can absorb vibration and noise.

3. Zinc Die Casting

Advantages of Zinc Die Casting

- High strength and hardness

- Excellent electrical conductivity

- High thermal conductivity

- Low cost raw material

- High dimensional accuracy and stability

- Excellent thin wall capability

- Ability to cold form, which eases joining

- High quality finishing characteristics

- Outstanding corrosion resistance

- Full recyclability

Zinc Die Casting Applications

- Complex net-shaped zinc housings, with precise thin walls offer excellent electrical performance and shielding properties

- Our proprietary multi-slide die casting process and superior thin-wall capabilities make us the foremost supplier of zinc components for broad range of consumer electronic devices

- The castability of zinc, its wear resistance, and structural integrity make it perfect for the creation of the multi-faceted, highly complex shapes used in automotive safety and electronics industry

Conclusion

As you’ve seen, there are many details to the Aluminum/Magnesium/Zinc alloys and the die casting process. If you’ve decided to go with die casting for your project, the next step is to figure out which alloy is ideal for your part’s specific application. Each alloy features the physical and mechanical properties required by the end product application, so it is usually determined by engineering design standards. As a result, you should look for a die casting provider who is familiar with each type of alloy available and the associated benefits so that they can guide you in the right direction. Contact GEMS representative now to discover more about which die casting process work best for your component manufacturing that leads to successful project.

Full Range of Die Casting Manufacturing Solutions @GEMS-MFG.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

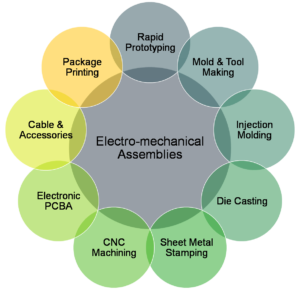

GEMS Manufacturing Ltd, based in Shenzhen China, have been providing Plastics, Metal & Electronic Part and Electro-mechanical Assembly Integration Services, which allows our customers to find all their manufacturing needs in one place. At GEMS we understand the importance of cost down manufacturing with flexible solutions, joining us with the industry’s best network of manufacturing talents, tools and facilities. Up-to-date we have shipped hundreds of containers to USA, UK, EURO and other oversea markets.

To learn more about how GEMS Manufacturing can help improve your production timeline for Integrated Product Development (IPD) and resolve your supply chain challenges, contact us or request a quote when needed.