Sustainable packaging is defined as the procurement, development, and usage of packaging solutions with a low environmental impact and footprint. Simply put, sustainable packaging is eco-friendly and does not contribute to additional natural resource depletion.

Many of us heard the term “reduce, reuse, recycle”, and today it’s critical that you reflect these same values in your business. Not only to benefit the environment, but also to boost brand loyalty among eco-conscious consumers. A recent study by Gartner found that –

- 37% of U.S. consumers prioritize sustainability when making buying decisions.

- 51 % of supply chain professionals expect the circular economy to expand in popularity in the next two years

- 30% of consumers are willing to pay a premium for products that deliver on sustainability claims.

Below GEMS-MFG lists 6 Strategies we propose to build sustainable packaging:

- #1 Design to eliminate product waste

Reducing your environmental footprint can be as simple as lowering the packaging materials you consume. This means design your product packaging with smaller or less boxes, bags, and containers. Not only does this help you be more sustainable, it can also save your shipping costs. If possible, play around with the size and positioning of your products to see if they can fit into smaller packages. For examples, if selling an office chair that can be disassembled, you can explore with several methods to position the various components and sub-assemblies of your product to see which method saves the most room. For shipping DIY, displaying or any other foldable products please pack them tightly folded, bundled or sub-assembled, so they’ll fit properly into smaller boxes.

- #2 Use recyclable packaging materials to the maximum

Make your packaging an extension of your brand and choose materials that make the most sense for your brand. Recycled packaging is a terrific technique to extend the life of previously used materials. When choosing boxes, mailers or containers, it is deserved to consider using packaging produced from recycled materials. One of the most frequent types of recycled packaging is paperboard or cardboard, which is made from recycled paper pulp. Besides, it’s light and easy to cut and shape, making it excellent for shipping boxes. Containers and mailers constructed from previously used plastic materials, such as single-use bags and bottles, are also an option. These polymers are treated at a recycling plant before being re-circulated as packaging supplies.

- #3 State guidance to consumer on sustainability

It is critical to provide specific information or guidance on any claims made consumers concerning the packaging’s appropriate disposal or environmental qualities. It includes information on the label to assist consumers to reduce their waste. If the product should be recycled, include information on how the consumer can recycle the packaging properly. If the product is compostable, include information on how the consumer can compost it effectively. If the packaging is reusable, let the consumer know how they can reuse it.

- #4 Avoid over-packaging throughout the supply chain

It is common to see packing materials are over abundant in some supply chain, especially for consumer and retail fields. Products can be inserted, bagged, wrapped, bundled and boxed before they get to you, often using far more than enough packaging materials. For example, one manufacture didn’t use customized carton to pack tablets in varied screen inches and then fill the empty space with useless materials from wobbling. Therefore, you are supposed to collaborate with your suppliers and partners to improve your supply chain operations so that these wastes they might generate are eliminated.

- #5 Source from manufacturing partners with sustainable practices

Choose to work with packaging manufacturers who honor the sustainability. Do your homework. Before signing a contract with a supplier, you have the right of visiting their location to inspect their facilities, equipment, and supplies. Also, inquire about their manufacturing processes and practices for using sustainable materials and reducing their environmental impact. You may then make a wise decision about whether or not to cooperate with them.

- #6 Change your sustainable packaging steadily

If you try to change everything at once, you may overwhelm yourself and your team that your initiatives will be poorly implemented. For starters, introducing new materials and methods requires extensive research, testing, and even trial and error. Take things slowly to make your sustainable packaging. Start with one or two items rather than replacing all of your supplies with greener alternatives. This is a crucial step to take, especially if you’re dealing with a new sustainable packaging option. Order modest quantities of the packaging materials and compare them to your existing packaging in terms of durability, client reception, and overall performance. You can go to larger sizes depending on the outcomes of your efforts.

Conclusion

As a responsible manufacturing company, GEMS shares the vital objective of removing packaging waste from the ocean and environment, and we want to be a part of that solution. Our customers and consumers are at the centre of everything we do. We understand that they are looking for more environmentally-friendly, sustainable packaging for on-the-go consumption. With our extensive knowledge and skills in the packaging industry, GEMS can assist in the implementation of sustainable packaging. We’ll continue to accelerate this journey through supplying more innovative, sustainable, and convenient packaging options to our clients.

Contract Manufacturing Solutions For Sustainable Packaging @GEMS-MFG.

Contract Manufacturing Solutions For Sustainable Packaging @GEMS-MFG.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

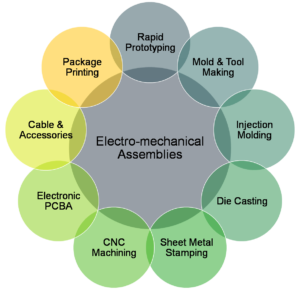

GEMS Manufacturing Ltd, based in Shenzhen China, have been providing Custom Metal, Plastic, Rubber & Electronic Part and Electro-mechanical Assembly Integration Services, which allows our customers to find all their manufacturing needs in one place. At GEMS we understand the importance of cost down manufacturing with flexible solutions, joining us with the industry’s best network of manufacturing talents, tools and facilities. Up-to-date we have shipped hundreds of containers to USA, UK, EURO and other oversea markets.

To learn more about how GEMS Manufacturing can help improve your Sustainable Packaging for Integrated Product Development (IPD) and resolve your supply chain challenges, contact us or request a quote when needed