Prototyping is a crucial part of the New Product Development (NPD) process, but traditionally it has been a bottleneck. Traditional manufacturing processes like injection molding require costly tooling and setup, which makes low-volume, custom prototypes prohibitively expensive. With the manufacturing technology develops, a new process called Rapid Prototyping quickly assumes its hold in the industry. Rapid prototyping, mainly consist of 3D printing and CNC machining, helps companies turn ideas into realistic proofs of concept, advances these concepts to high-fidelity prototypes that look and work like final products, and guides products through a series of validation stages toward mass production.

Prototyping is a crucial part of the New Product Development (NPD) process, but traditionally it has been a bottleneck. Traditional manufacturing processes like injection molding require costly tooling and setup, which makes low-volume, custom prototypes prohibitively expensive. With the manufacturing technology develops, a new process called Rapid Prototyping quickly assumes its hold in the industry. Rapid prototyping, mainly consist of 3D printing and CNC machining, helps companies turn ideas into realistic proofs of concept, advances these concepts to high-fidelity prototypes that look and work like final products, and guides products through a series of validation stages toward mass production.

3D printing is a fast-evolving technology that offers numerous advantages over traditional manufacturing processes. It does, however, have disadvantages, such as the fact that 3D printing cannot be applied for mass production and is limited in terms of speed and accessibility. CNC machining (computer numerical control), a common subtractive process for part creation, is another manufacturing technique for low-to-mid volume. To understand and determine which technology is more appropriate for specific application with varied conditions, we decided to compare the advantages and disadvantages of both 3D printing and CNC machining from different perspectives.

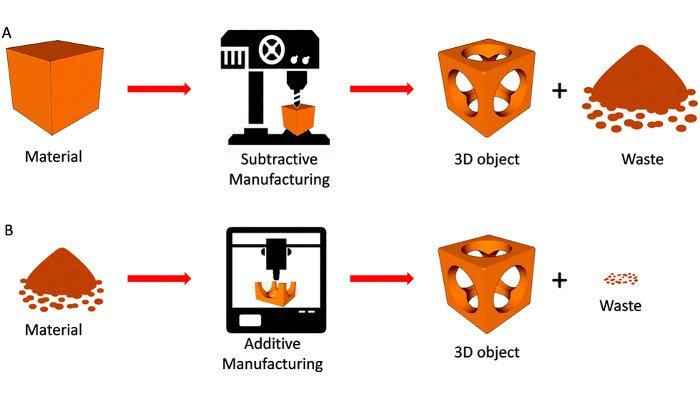

1. Subtractive or Additive Manufacturing

Subtractive manufacturing starts with solid blocks, bars, rods of plastic, metal, or other materials that are shaped by removing material through cutting, boring, drilling, and grinding. In contrast to the subtractive manufacturing of removing material from a larger piece, additive manufacturing builds objects by adding material one layer at a time, with each successive layer bonding to the preceding layer until the part is complete. Obviously the main difference between 3D printing and CNC machining is that 3D printing is an additive manufacturing, whereas CNC machining is a subtractive manufacturing.

Both 3D printing and CNC machining are compatible with a wide range of materials, including both plastics and metals. 3D printing primarily focuses on plastics, though this is rapidly changed as companies like 3D Systems, Arcam, Desktop Metal, and Markforged have created better and more affordable machines for 3D printing metal.

In 3D Printing, commonly used thermoplastics include ABS, PLA, Nylon, ULTEM, but also photo-polymers such as wax, calcinable or biocompatible resins. Some niche 3D printers also allow for the printing of parts in sand, ceramics, and even living materials. The most common metals used in 3D printing include aluminum, stainless steel, titanium and inconel. It is also worth noting that expensive industrial machines are required to 3D print metal. Some materials such as superalloys or TPU (flexible material) cannot be created with CNC, so must be used with 3D printing or rapid tooling technology.

For CNC Machining, the most common plastics used include ABS, Nylon (PA66), Polycarbonate (PC), Acrylic (PMMA), Polypropylene (PP), POM and PEEK. A common metal used in CNC machining is Aluminum, which is popular to manufacture high-quality prototypes in a range of industries. Aluminum is recyclable, has good protective qualities, and can create effective prototypes for machining. Other commonly used metals include stainless steel, magnesium alloy, zinc alloy titanium, and brass.

For CNC Machining, the most common plastics used include ABS, Nylon (PA66), Polycarbonate (PC), Acrylic (PMMA), Polypropylene (PP), POM and PEEK. A common metal used in CNC machining is Aluminum, which is popular to manufacture high-quality prototypes in a range of industries. Aluminum is recyclable, has good protective qualities, and can create effective prototypes for machining. Other commonly used metals include stainless steel, magnesium alloy, zinc alloy titanium, and brass.

2. Cost, Accuracy & Size limitations

Early concept models and prototypes are generally more economical and faster to produce with plastic 3D printing. 3D Printing offers a wide range of material alternatives for the functional prototyping of plastic parts. Additive manufacturing is also better suited to small parts and highly complex or intricate designs.

When later stages of the development process require larger batches, CNC machining becomes more competitive. Larger, less complex products are likewise better suited to subtractive manufacturing. CNC machining is frequently used to fabricate finished parts because to the wide range of surface treatments available and the speed of the processing. As metal 3D printed parts can be cost-prohibitive, CNC machining is a preferable option for all metal pieces but the most complex designs.

3. Ease of Use

3D printing is known to be less difficult to operate than CNC machining. This is because, once the file for 3D printing has been prepared, all what you have to do is to select the part orientation, fill and supports if needed. After that, there is no need for a supervisor, and the printer can be left till the part is finished. Post-processing requirements is determined by the technology.

CNC machining, on the other hand, is a far more labor-intensive process. A skilled operator is required to choose different tools, rotation speeds of tools, the cutting path, and any repositioning of the material the part is being created from. There are also post-processing processes that can take a long time to complete.

4. Main Applications

3D printing (Additive manufacturing) is perfect for prototyping, producing tooling, and casting patterns, as well as short-run, bridge production, and custom manufacturing of final products in a variety of technical and manufacturing applications. 3D printers provide a high degree of design freedom and may build complex designs that would be impossible or excessively expensive to produce using any other processing method.

CNC machining (Subtractive manufacturing) processes are commonly used to build prototypes, production tools, and end-use parts in plastics or metals. They’re perfect for applications requiring tight tolerances and geometries that are difficult to mold, cast, or fabricate using traditional manufacturing methods.

Due to their overlapping range of applications, 3D printing and CNC machining are frequently used side by side, despite their fundamental differences.

Conclusion

To summarize, there is no perfect, one-size-fits-all method. Despite the fact that both 3D printing and CNC machining are capable and beneficial, the most appropriate one will be determined by the material, geometric complexity, manufacturing volume, and budget. To find out which is ideal for your specific work, we recommend you to contact a local or international service provider and ask for their advice.

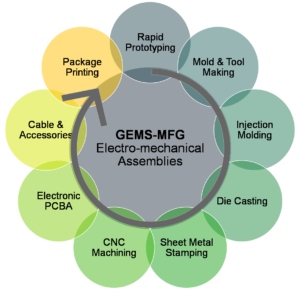

RAPID Prototyping to New Product Development @GEMS-MFG

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimu

m reliable product provider like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

GEMS-MFG, based in Shenzhen, China, has been providing Manufacturing Solutions for Custom Metal, Plastic, Rubber and Electronic Part and Electro-mechanical Assembly Integration Services to USA, UK, EURO and other oversea markets. Current supply chain issues have highlighted the need for more reliable ONE-STOP manufacturer like GEMS Manufacturing, who you can trust to support your business like your own eyes and hands in China when you are inconvenient to travel.

To learn more about how GEMS Manufacturing can help improve your manufacturing timelines for New Product Introduction (NPI) and resolve your supply chain challenges, contact us or request a quote today.