Value Added Service: CNC Machining in Shenzhen, China

— Computer numerical control (CNC) machining is a subtractive manufacturing method that uses computer programming to direct the movement of machining equipment and tooling to create custom-designed parts and products. Manufacturers employ a wide range of machining operations and machines to suit varying part designs and production specifications. CNC machined components are available in a wide range of sizes, shapes, and materials and range from simple to complex geometries. We machined parts from many different plastic and metal materials on our state of the art machining finishes available CNC Machining is a very versatile option. Fast, accurate and competitively priced whilst delivering superior surface finishes from a massive range of material options,

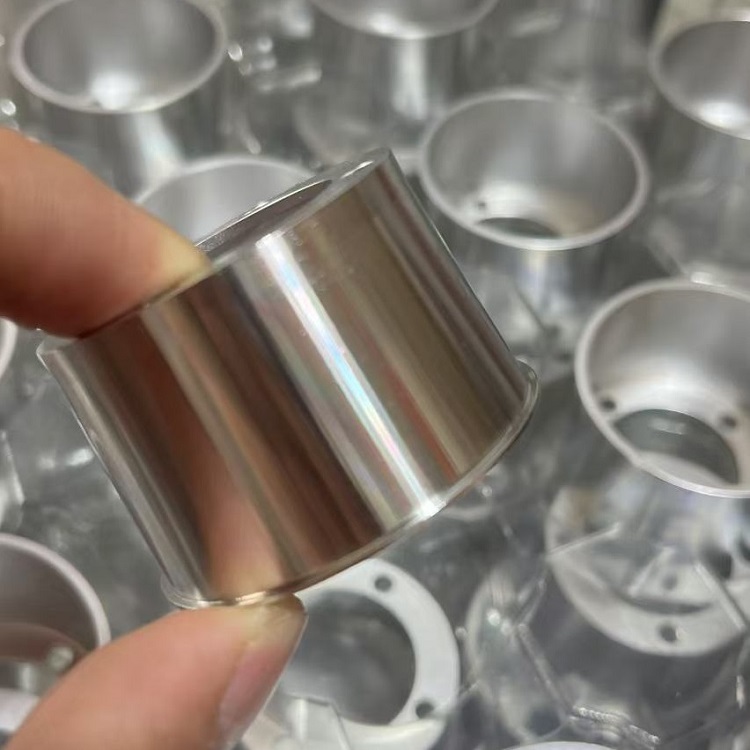

At GEMS-MFG, our facility houses a fully equipped machine shop with precision capabilities. We have both 4-axis and 5-axis multi-tasking CNC machining centers that we use for milling, boring, turning and threading, etc. Furthermmore, we produce high accuracy die casting parts and many of them require secondary machining. Our tooling designers, casting technicians and machinists work as a team to facilitate the process. We have exceptional skills in designing dedicated fixtures and establishing machining setups that correctly orient and align die-cast parts for accurate and repeatable results. Our operators obtain precision accuracy when machining aluminum, magnesium, and zinc die castings with elaborate designs and critical tolerance requirements. Able to operate at fast speeds and perform simultaneous cutting, our equipment allows us to accelerate cycle time. With our machining expertise, we can meet the challenges of key dimensional and cosmetic inspection criteria.