IV. Benefits of LSR Injection Molding

Liquid Silicone Rubber (LSR) Injection Molding offers a host of advantages, making it a preferred choice in manufacturing processes.

4.1. High Precision:

LSR Injection Molding enables the production of highly detailed and intricate components with exceptional precision. The process ensures that even the most complex geometries and fine details are faithfully reproduced in the final product.

4.2. Efficiency and Cost-Efficiency:

This method minimizes material waste and reduces production time, contributing to cost-effectiveness. The efficiency of LSR Injection Molding makes it an economically viable solution for industries seeking high-quality components without excessive resource consumption.

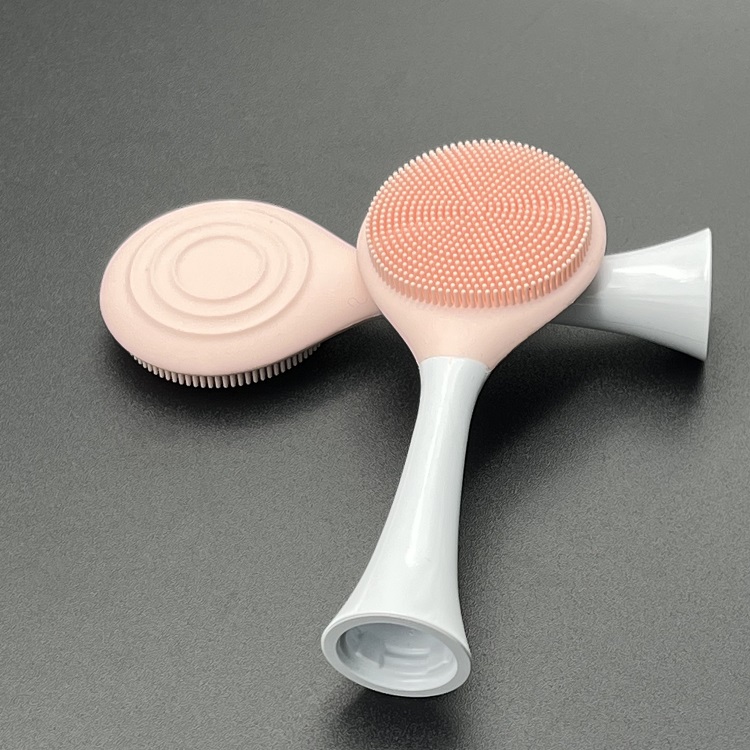

4.3. Versatility:

LSR Injection Molding’s adaptability to a broad range of applications is a standout feature. The material’s durability, flexibility, and resistance to temperature extremes and chemicals make it suitable for diverse industries, including medical, automotive, and consumer goods.

4.4. Biocompatibility:

LSR is biocompatible, making it ideal for medical and healthcare applications. Its hypoallergenic nature and compatibility with the human body position it as a trusted material for the manufacturing of medical devices, implants, and other critical components.

4.5. Consistent Quality:

The controlled nature of the injection molding process ensures consistent quality in each produced item. This is particularly crucial in industries where precision and uniformity are paramount, such as medical or electronic component manufacturing.

4.6. Reduced Labor Intensity:

LSR Injection Molding can be automated, reducing the reliance on manual labor. Automation enhances efficiency, reduces the likelihood of errors, and contributes to a more streamlined production process.

4.7. Resistance to Extreme Conditions:

LSR exhibits high thermal stability and resistance to chemicals, making it suitable for applications in challenging environments. It maintains its integrity and performance even under extreme temperatures and exposure to various chemicals.

4.8. Environmental Friendliness:

The reduction in material waste and efficient production processes contribute to the environmental friendliness of LSR Injection Molding. Minimizing resource consumption aligns with sustainable manufacturing practices.

In summary, LSR Injection Molding’s benefits encompass precision, efficiency, versatility, and the ability to meet stringent quality standards. Whether in medical, automotive, or consumer goods industries, the advantages of LSR Injection Molding position it as a reliable and innovative solution in modern manufacturing.

![]()