Value Added Service: Rapid Prototyping Services in Shenzhen, China

— Why is it important to prototype your part before a production tool is made? Because one small mistake that you may not be visible could cost you (or us) thousands of dollars later! Rapid prototyping creates the possibility to communicate and visualize design ideas, whether you are developing a new product or even require end-user parts.

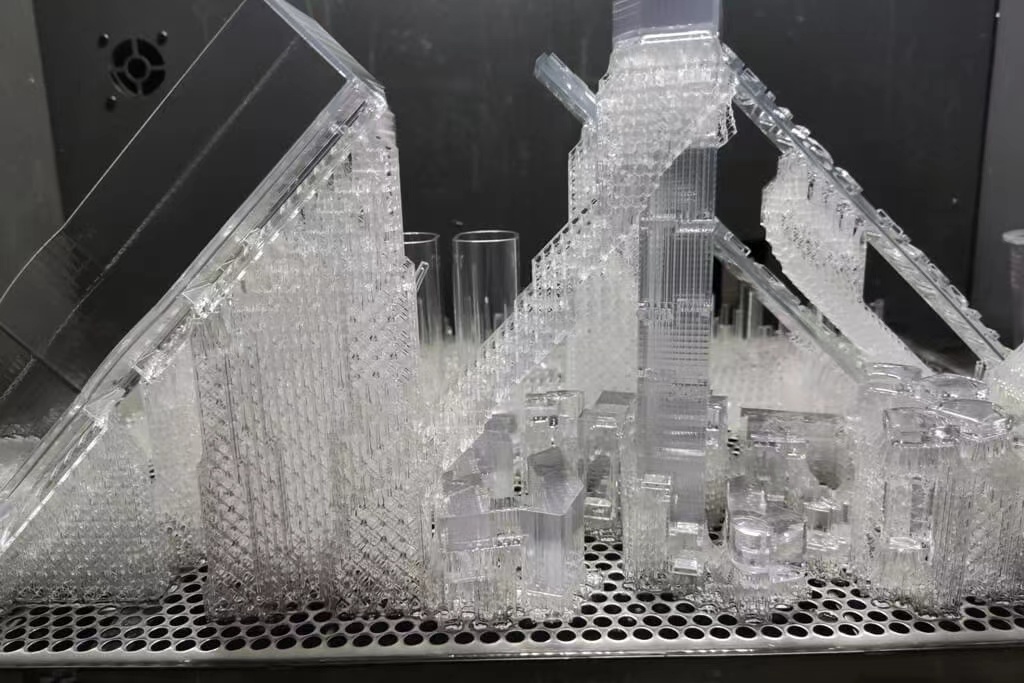

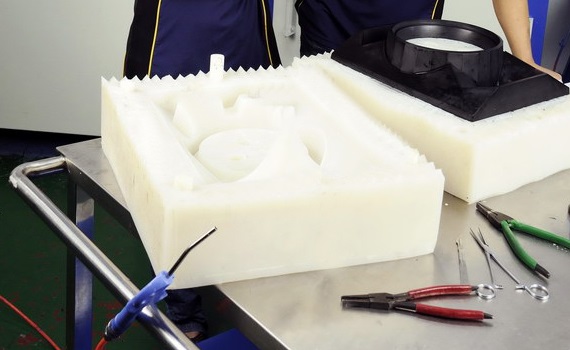

A rapid prototype part is a process of using a 3D CAD Model of a part and replicating that model into a physical part. There are a few different options when considering a rapid prototype. Some types will not hold up to testing and others will. We leverage several different methods for prototyping based on the stage of product development and specific customer requirements, which mainly include 3D Printing, CNC Machining, Soft Steel Mold and Silicone Mold (or Vacuum Casting).

With our advanced prototyping capabilities, we can quickly produce physical prototypes for testing and validation, ensuring that the final product meets the desired specifications. Once the prototype has been approved, we seamlessly transition into the production phase. Our state-of-the-art manufacturing facilities are equipped with advanced machinery and technologies, enabling us to produce high-quality metal, plastic, and silicone products with precision and efficiency. Our team closely monitors the production process to ensure utmost quality control and adherence to project timelines.