I. Introduction to Vacuum Casting

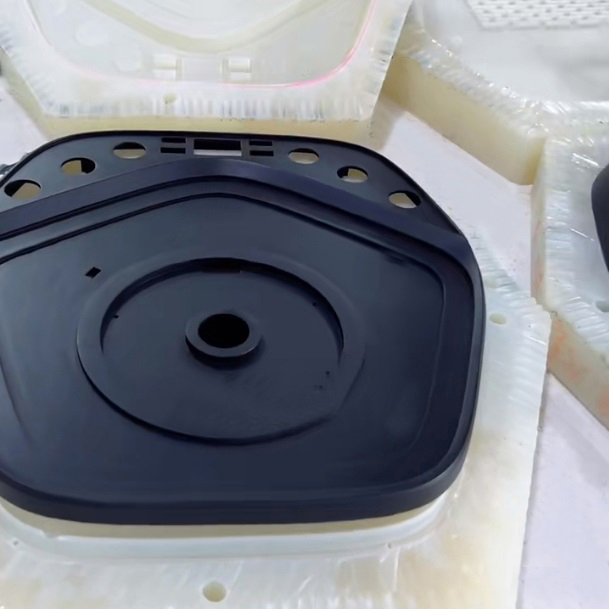

Vacuum casting is a manufacturing technique that bridges the gap between concept design and product realization, making it an essential tool for new product development. This process involves creating high-quality prototypes and low-volume production parts using flexible silicone molds and a variety of polyurethane resins. Unlike other manufacturing methods that may require expensive tooling and long lead times, vacuum casting offers a cost-effective, rapid alternative, allowing designers and engineers to iterate and refine their products quickly.

By utilizing silicone molds and polyurethane resins, this process bridges the gap between concept design and physical prototype. It allows manufacturers to produce accurate, detailed parts quickly and at a fraction of the cost associated with traditional manufacturing techniques, such as injection molding. With its ability to replicate intricate details and simulate production-grade materials, vacuum casting is a powerful resource for industries ranging from automotive to medical devices. It empowers product developers to efficiently move from the concept phase to functional prototypes, making it a valuable asset in the fast-paced world of innovation.