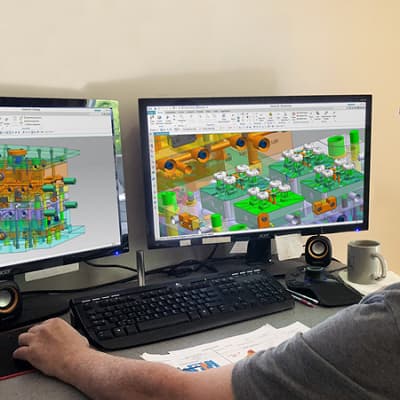

Metal Parts can be produced through various manufacturing processes, such as CNC Machining, Die Casting and Sheet Metal Stamping, while one may have advantages and disadvantages from another. With decades manufacturing experience & expertise in industrial parts, GEMS-MFG well understand the differences of multiple metal forming methods. In order to assist you in achieving the desired part attributes, including but not limit to strength, heat and electrical conductivity, aesthetics, surface protection, corrosion resistance and others, we will discuss and recommend the best manufacturing process for your application.

Taking Die Casting for example, it is a manufacturing process that pours or injects molten metals into molds, which allows each part to be generated with accuracy and repeatability. Die casting is a productive, affordable process that offers a wider variety of shapes and parts than any other production method. Parts can be made to suit the counterpart’s aesthetic and have a long service life. Designers can benefit from die cast parts’ fast production, tight tolerances, dimensional precision and stability, strength, variety of surface finishes, and streamlined assembly processes.

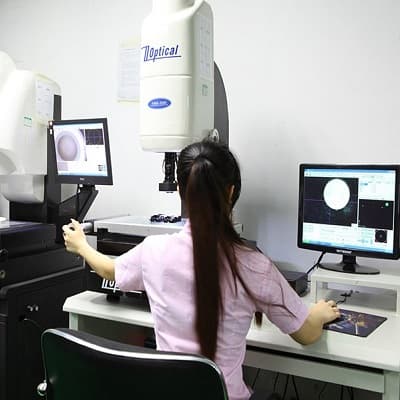

Our metal parts are concentrated on the applications of medical, automotive, renewable energy, lighting and electronics, home appliance, machinery, furniture, industrial tools and others. To know details about our engineering and manufacturing capabilities for metal parts and how we serve the above industries, please contact us right today.

LIGHTWEIGHT FISHING TOOL COMPONENTS ALUMINUM CNC MACHINING SUPPLIER IN CHINA

LIGHTWEIGHT FISHING TOOL COMPONENTS ALUMINUM CNC MACHINING SUPPLIER IN CHINA FACTORY CRITICAL MEDICAL DEVICE COMPONENTS MANUFACTURER

FACTORY CRITICAL MEDICAL DEVICE COMPONENTS MANUFACTURER HIGH PRECISION ALUMINUM DIE CASTING LAMP LED LIGHTING COMPONENTS MAKER

HIGH PRECISION ALUMINUM DIE CASTING LAMP LED LIGHTING COMPONENTS MAKER TOP QUALITY METAL HOUSING BOX ELECTRONIC ENCLOSURE MANUFACTURERS

TOP QUALITY METAL HOUSING BOX ELECTRONIC ENCLOSURE MANUFACTURERS MAGNESIUM DIE CASTING PARTS FACTORY CUSTOM DESIGN CELL PHONE MIDDLE FRAME

MAGNESIUM DIE CASTING PARTS FACTORY CUSTOM DESIGN CELL PHONE MIDDLE FRAME CHINA ZINC ALLOY DIE CASTING PRODUCTION DIE CAST COMPONENTS MANUFACTURER

CHINA ZINC ALLOY DIE CASTING PRODUCTION DIE CAST COMPONENTS MANUFACTURER