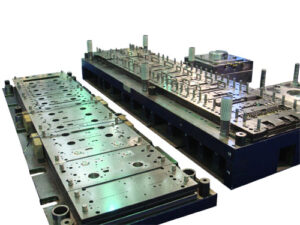

Sheet Metal Stamping Tool, Stamping Mold, Stamping Die

Sheet metal stamping tools or stamping dies are used to produce high precision metal components which are identical in shape and size. The dimensional accuracy and stability that can be achieved using precision metal stamping dies are very high and thus metal stamping dies are integral part of any manufacturing industry. Stamping die manufacturing involves step by step operations starting from design study, planning, pre-machining, heat treatment, final machining, bench fitting and assembly. Dies also can contain cutting and forming sections made from carbide or various other hard, wear-resistant materials.

Stamping dies can be a simple single stage tool where a component or operation is completed in every stroke of the stamping die or it can be a progressive stamping die where a series of various stamping techniques are performed in different stages to produce complex shaped metal stamping parts. You can see metal stamping components everywhere. From the electrical switches at your home to the computer you are surfing, from cars to aircrafts, everything needs precision metal stamping parts. Metal stamping dies can be used for various sheet metal operations like, shearing, blanking, piercing, bending, forming, coining, embossing, extrusion, deep drawing etc. It is used for making aluminum tubes, cans and lids.

Sheet Metal Stamping Material Considerations

Metal stamping is a cold-forming process that makes use of stamping tools and presses to transform sheet metal into different shapes. Pieces of flat sheet metal, typically referred to as blanks, is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape. Metal operators offering stamping service will place the material into production facilities to be stamped between die sections, where the use of pressure will shape and shear the material into the desired final shape for the product or component.

The choice of metal stamping materials used depends on the desired attributes of the finished piece. Stamping is not limited as a fabrication process to just metals – there are numerous metal stamping materials that can be processed through stamping techniques, such as paper, leather, or rubber, but metals are by far the most commonly used.

In general, metals tend to maintain their malleability and ductility after stamping. Those used in precision stamping usually range from soft to medium hardness and carry a low coefficient of flow. Some of the customary metals and metal types fabricated through stamping include:

- Precious metals, such as silver, gold, and platinum

- Ferrous metals, especially iron-based alloys like stainless steel

- Non-ferrous metals, such as bronze, brass, and zinc

- Non-standard alloys, such as beryllium nickel and beryllium copper

- Ferrous metals are commonly used in stamping operations, as their low carbon content means they are among the least expensive options available resulting in low unit production costs.