Metal Alloys Die Casting Manufacturer in China

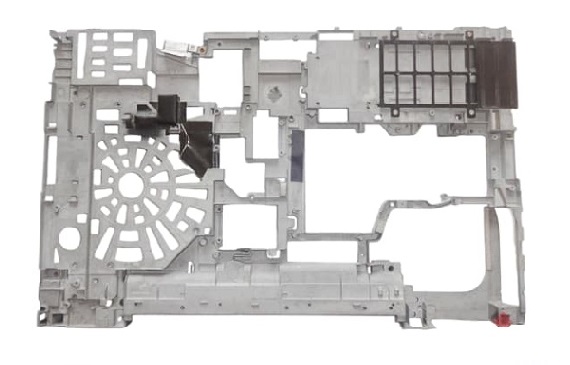

— Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Die castings are characterized by a very good surface finish and dimensional consistency.

Die casting is commonly used for producing a wide range of metal parts, including components for the automotive industry (such as engine blocks, transmission housings, and steering components), consumer electronics, appliances, and industrial machinery. The process offers several advantages, including high precision, repeatability, and the ability to produce complex shapes with tight tolerances. Additionally, die casting can be a cost-effective method for high-volume production due to its efficiency and minimal material waste.

At GEMS-MFG, we seamlessly integrate cutting-edge metal die casting techniques with Lean production principles to expedite the introduction of your products to the market—enhancing efficiency, speed, and intelligence. Acknowledged for our operational prowess and commitment to quality, especially in highly regulated sectors, we assist in materializing your vision. Our expertise spans from the initiation of new product launches to the meticulous assembly of high-level systems and the seamless handling of ultra-high volume automated assembly processes through metal die casting. Additionally, we are dedicated to optimizing productivity, elevating quality standards, enhancing responsiveness, and refining the precision of decision-making at every stage of the product lifecycle.