Manufacturing Services FAQs

WHAT MANUFACTURING SERVICES DO YOU OFFER?

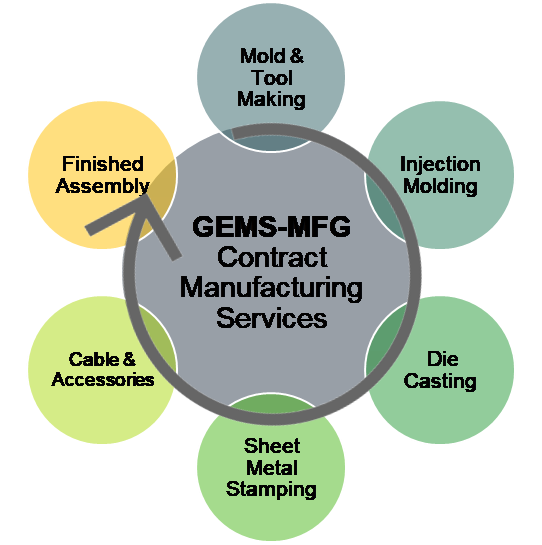

Our core contract manufacturing services consist of Tool & Mold Making, Injection Molding, Die Casting, Sheet Metal Stamping and Finished Assembly, as well as certain Value Added Services.

WHAT VALUE ADDED SERVICES DO YOU OFFER?

Value added services are certain manufacturing services, which go above and beyond our core technologies GEMS Company already offers to clients, for components or accessories, such as Rapid Prototyping, PCBA, Cable, Package and etc. These supplemental services could help clients customize their needs through collaboration with only one contract manufacturer to increase efficiency & capacities and remain competitive in their marketplaces.

ARE YOU TRADING COMPANY OR MANUFACTURING FACTORY?

Due to the rapid growing production costs in Shenzhen for Land, Labor & Capital, our self-owned manufacturing facilities have been relocated to Dongguan. Currently GEMS-MFG in Shenzhen China is a trading company in a platform environment to improve the overall customer experience by simplifying the supply chain management through our manufacturing network in Shenzhen, Dongguan, Foshan, Xiamen and Changzhou and other areas.

WHAT MATERIALS DO YOU HAVE?

We are familiar with a wide range of over 200 materials across our comprehensive manufacturing service lines, including but not limited to Steels for Tool & Mold Making, Plastics and Silicone Rubbers for Injection Molding, Metal Alloys for Die Casting and Sheet Metal Stamping Materials. However, we cannot guarantee the availability of all particular materials.

WHAT IF I AM NOT SURE THE RIGHT MATERIAL?

In some scenarios, if the designer hasn’t finalized the best material for your product application, you can write down the material you ever thought about and share us the application conditions of finished product in the notes section, our engineer may suggest optional materials that are available for your further reviewing.

CAN YOU PROVIDE A CERTIFIED REPORT FOR THE RAW MATERIAL?

Yes, we understand the importance of material origin and always purchase the raw material from reliable authorized resource, so it is never an issue for us to get the certified reports from steel or resin manufacturers like Data Sheet, MSDS, ROHS and other testing compliance reports.

DO YOU OFFER OVERSEAS OR EXPORTED MOLD MANFUACTURING?

Yes, exported mold is a key business of our service scope. After an overseas mold is functionally operational and capable of making the part for which it was designed and built to print, we will apply mold approval from customer with a strict validation process before the exporting, although most clients decide to run and keep their massive production at GEMS Manufacturing. No matter you require a plastic injection mold made & exported to run at your facility or thousands of excellent finished items packed in gift boxes for container shipment, we are confident to fulfill your demand, being a fantastic asset to your supply chain.

CAN YOU ACCEPT MOLD & PROJECT TRANSFER FROM CUSTOMER OR AUTHORIZED THIRD PARTY?

Yes, we are willing to show our hand whenever a customer encounters manufacturing issues to our specialty. GEMS commits to providing technical assistance, troubleshooting and on-site service for any China basis project falling into our contract manufacturing service, whether GEMS is the first one to built it or not, from concept design to finished product delivery.

WHAT KIND OF SILICONE RUBBERS ARE YOU IN FOR INJECTION MOLDING?

Liquid silicone rubber (LSR) and High consistency rubber (HCR) are two families used in our injection molding. HCR is also called solid silicone rubber, VS liquid silicone rubber.

Liquid silicones are generally made from two part systems that are mixed and heat cured inside the injection mold. HCRs are often mixed and supplied to manufacturers in gum form to be compression molded or rotocured into sheets.

ARE YOU CAPABLE OF BUILDING MULTI-COLOR PART?

I would say YES. Multi-color injection molding is formed by multiple plastics or different colors of one plastic into an end product through one injection molding process.

2K Molding is well known as 2 shot injection molding or two-color injection molding, which is the most common injection molding method we produced power tool products.

WHAT TYPE OF METAL ALLOY DO YOU USED IN DIE CASTING?

Types of metal materials we use for die casting: Magnesium Alloy, Aluminum Alloy and Zinc Alloy.

They are featured with several metals’ desirable properties, such as reduced weight, increased conductivity, non-magnetic conductivity and corrosion resistance, which allow them to fit almost every type of application a manufacturer may need.

WHAT IS YOUR MINIMUM ORDER QUANTITY?

MOQ is never an issue for our production. We can build to order from 1 to 100,000 pieces across our manufacturing services. Of course, the higher volume will benefit from more competitive price. It is critical for clients to share the forecast of coming demand in advance, so as to reserve enough raw materials and processing capacities.

CAN I CUSTOM MAKE THE PRODUCT COLORS AND TEXTURES?

Yes, we support different product surface finishing used to alter the appearance of a part in texture, smoothness and color for functional or aesthetic reasons. The options we provide include “As machined/ Anodizing/ Plating / Powder Coating/ Black Oxidize/ Brushed/ Polishing/ Spraying….”

Bear in mind that varied surface finishes are appropriate for varied materials and manufacturing techniques.

CAN YOU DESIGN A PART FOR ME?

Strictly speaking, No, although it is quite often we help clients turn in the part design when running DFM. GEMS focuses on contract manufacturing rather than R&D design services. We need a CAD file of your product to provide a quote. Additionally, this implies that we are unable to produce parts from a photograph or physical duplicate.

HOW DO YOU MANAGE THE QUALITY ASSURANCE?

We split our quality control process into three stages: Pre-production, In production and Before delivery inspection. Soon upon shipment for all orders, we provide clients QA report covering the following aspects: Shipping quantity, Critical dimensions and tolerances, Cosmetic defects and Functional testing data etc.

Vision:

Vision: Mission:

Mission: Value:

Value: