Introduction

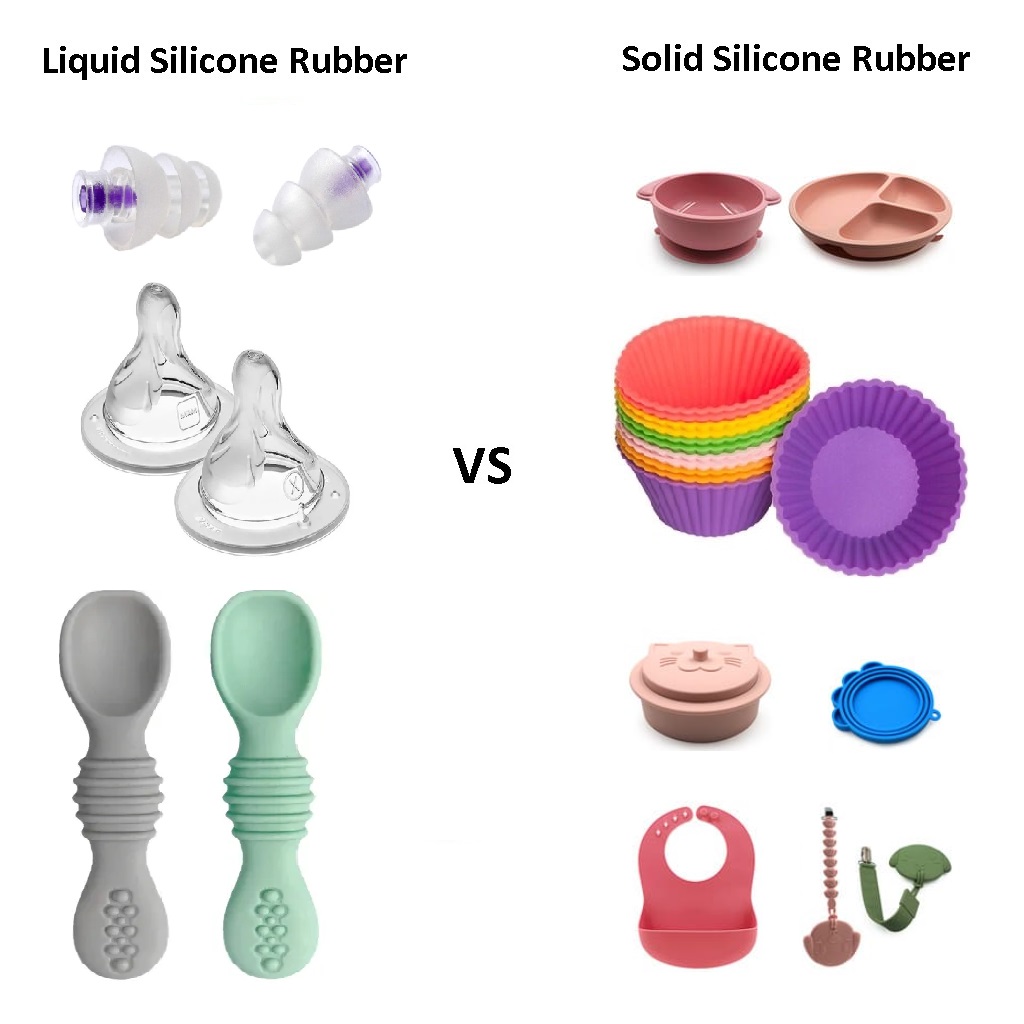

You could be mistaken in thinking that all rubber is the same. A particular type of rubber can perform tasks that standard rubber cannot. Silicone rubber is composed of silicon and other elements. It can be used for various due to its exceptional properties, including gaskets, electronic potting, medical devices, and formed parts. It exists in both liquid and solid states, so called Solid Silicone Rubber (SSR) and Liquid Silicone Rubber (LSR). While they share the base material, their physical states, processing methods, and material properties differ significantly.

In this comprehensive comparison, we delve into the distinctions between SSR and LSR, exploring their manufacturing processes, material properties, and applications. We will explain in this article why silicone rubber is the best option for your needs and how to choose between liquid and solid forms.

Note: Solid Silicone Rubber (SSR), also known as High Consistency Rubber (HCR), is cured at high temperatures with either organic peroxides or a platinum catalyst. SSR contains long polymer chains with a high molecular weight, which provides the rubber with a solid consistency.