Case Brief:

Liquid Silicone Rubber (LSR) manufacturing has a special place in GEMS’ history. As an early entrant to rubber mold making in the industry, we helped clients develop many molds and tools for silicone products that the industry still uses today. For a consumer product project, the famous brand customer needed to introduce a soft touch travel bottle to their sales channels worldwide before the coming summer holiday, as they forecasted a huge market opportunity if we could hit the market tendency earlier than other competitors. This required on a compressed time schedule maximum 4 months from tooling kick-off to massive production, while the client didn’t finalize the product specification by then.

![]()

How the Story Goes:

The Problem

The Problem

Liquid Silicone Rubber (LSR) manufacturing has a special place in GEMS’ history. As an early entrant to rubber mold making in the industry, we helped clients develop many molds and tools for silicone products that the industry still uses today. For a consumer product project, the famous brand customer needed to introduce a soft touch travel bottle to their sales channels worldwide before the coming summer holiday, as they forecasted a huge market opportunity if we could hit the market tendency earlier than other competitors. This required on a compressed time schedule maximum 4 months from tooling kick-off to massive production, while the client didn’t finalize the product specification by then.

Our Process

Our Process

After reviewing the customer expectations, GEMS understands it requires an entirely new project management team being developed that could meet the disparate requirements of each component and performance. Material, cleanliness, flexibility, appearance and cost were all critical aspects to be considered. More importantly, NO compromise allowed for the quality and the timeline. GEMS assigned the rubber talent resources, integrated the process technology, and configured each component for its material and process. To assure the project timeline, weekly conference call meetings were held to review the latest project progress at least once a week.

The Result

The Result

The client was happy with GEMS’s proposal to move forwards with liquid silicone rubber as the key material and applied a simple but eco packaging method to honor the environment friendliness, which later turned out to be welcomed by most consumers. With close communication with the clients and manufacturing partners, all parties are always refreshed on the same page and the project milestones were successfully hit or even pulled in. GEMS gained client’s production approval when submitting the 2nd batches of engineering samples, helping enable the timely market launch and high volume manufacturing supply within 4 months timeframe.

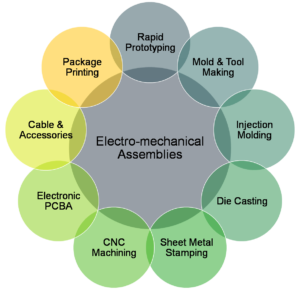

ONE-STOP Contract Manufacturing solutions @GEMS-MFG.

By simplifying the supply chain and maximizing the productivity are key ways to fight global supply chain issues caused by the COVID-19 pandemic, weather disasters, and other unpredictable events. When focusing supply by minimum reliable product providers like GEMS Manufacturing, customers can dramatically simplify the vendor management and speed up product development process, as well as boost quality assurance.

GEMS Manufacturing, based in Shenzhen China, has been providing custom Metal, Plastic, Rubber and Electronic Part and Electro-mechanical Assembly Integration Services to USA, UK, EURO and other oversea markets. The purpose of managing this company is to improve the overall customer experience by simplifying the supply chain management which allows our customers to find all their manufacturing needs in one place.

Current supply chain issues have highlighted the need for more reliable ONE-STOP manufacturer, who you can trust to support your business like your own eyes and hands in China when you are inconvenient to travel. To learn more about how GEMS Manufacturing can help resolve your product