Driving Results Through Operational Excellence @GEMS-MFG

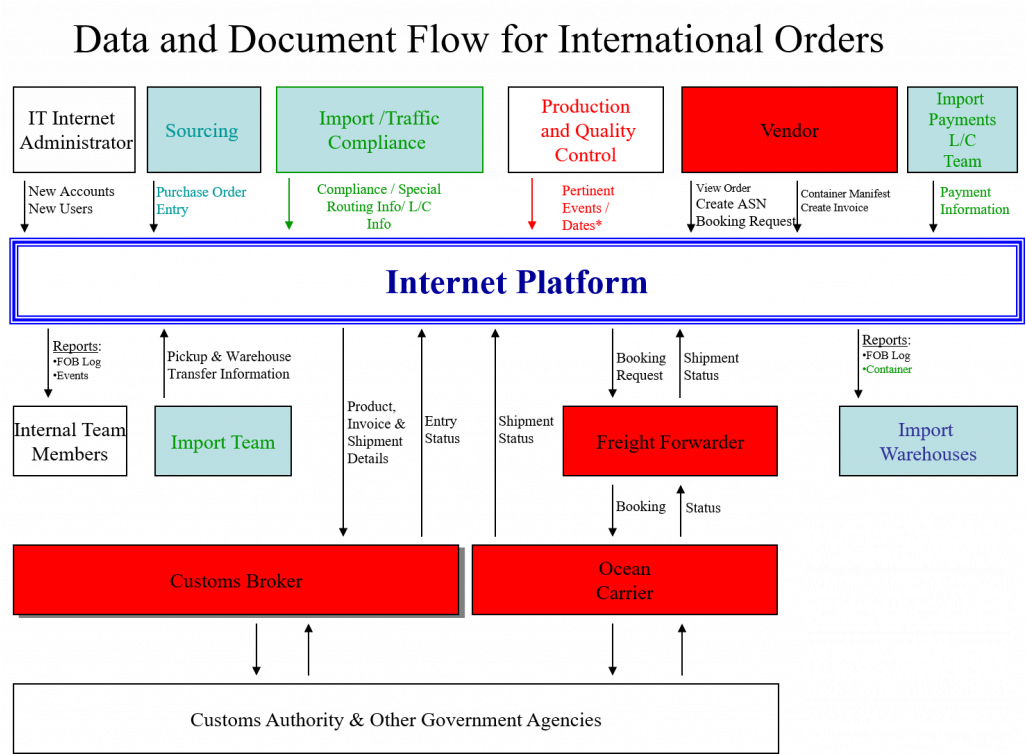

Without a doubt supply chain management has always been important to businesses, but it is now more so than ever as an indicator of success. Companies who can effectively manage their supply chain that is adapted to today’s unpredictable and rapidly changing, technology-driven business environment will survive and expand in an effective manner.

GEMS-MFG, as your ONE-STOP manufacturing solution supplier, is in charge of every stage of your supply chain, providing an unrivaled level of contract manufacturing services along the way.

1. Tailor Your Unique Demand with Custom Solutions

Your product requirements are unique, and so must your supply chain solution. We’ll listen to you and collaborate with your team to develop a solution that’s customized to your company’s expectations and the demands of your consumers. Our intelligent supply chain solutions for the whole product lifecycle assist you in gaining a competitive edge in your markets. From design and engineering through production and after-market services, we support you in reducing costs, improving speed-to-market and driving innovation across the board. GEMS Manufacturing also provides supply chain management services with short term warehousing and global logistics, so as to promote our partnership beyond the design and production stages.

2. Not Just Hard-working, Net-working

Having a stable, adaptable, and cost-effective supply chain in place is beneficial whether you create individual components, pre-assembled parts, or ready-to-sell finished product. GEMS does this through a network of local suppliers that has been developed over many years and is regularly monitored for quality and efficiency. For even better performance, GEMS applies its time-tested experience, procedures, and technologies to your supply chain. Your business will occupy much less time when operating with GEMS’ supply chain services, allowing you more time to focus on the FUTURE. Creating a more efficient and practical supply chain results in your company will spend little time worrying about “how” and enjoy more time for delivering. GEMS tackles each of your supply chain’s important factors through supply chain planning to provide end-to-end visibility, quicker full-cycle integration and predictable planning outcomes.

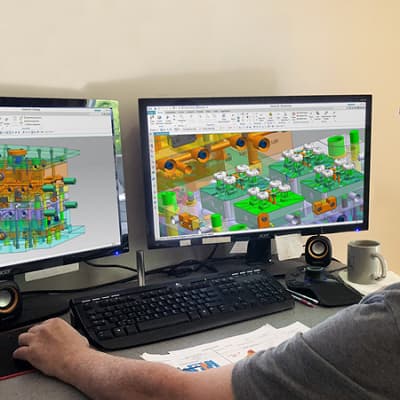

3. Streamling The Supply Chain Process

GEMS’ supply chain professionals ensure that all materials, tools, electronics, and services are suitable for your product’s requirements. Every new supplier is chosen and qualified using defined procedures to ensure that every component and service is reliable and of high quality. Suppliers are required to measure and test their goods and services on a regular basis to guarantee that they continue to supply the best materials and services. We make your production process smoother and more cost-effective by searching the industry for the most trusted and highest-quality suppliers. GEMS understands the critical role that supply chain services play in our customers’ companies and is committed to providing long-term solutions. We are uniquely positioned to provide commodities such as molds and tools, metal and plastic parts, printed circuit boards (PCB), and electro-mechanical assemblies, and we can achieve cost savings for our customers in manufacturing solutions with lower defect rates, higher efficiency, and shorter lead times, all of which are typically associated with more productive supply chain management.

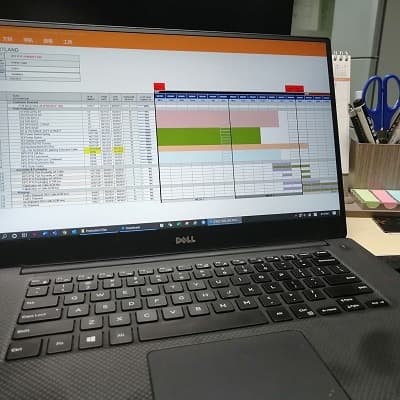

4. Time Management Tools To Boost Productivity

GEMS Manufacturing also offers Contract Kanban/JIT shipping to help clients streamline their supply chains and simplify their inventory control processes. These services help customers save money on shipping while also assuring that they get ready-to-use components or assemblies when needed. Our production lead times vary depending on the project’s complexity, but they normally range from 3 to 4 weeks and expedited service is available on demand. See our general capabilities list for more information about value added services, or contact us directly.

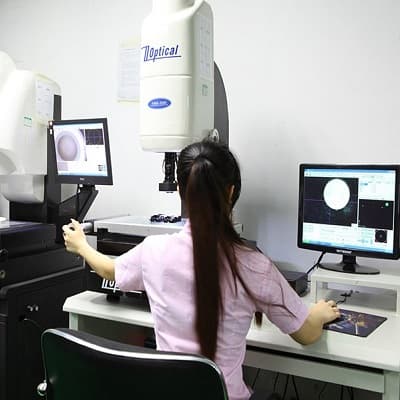

5. A Culture of Premium Quality and Continuous Improvement

Our culture, combined with a constant pursuit of continuous development, allows us to maintain our technology leadership and establish the electro-mechanical manufacturing industry standard for product quality. By providing the best quality of supply chain service and operation stability, we are committed to our customers’ success to the maximum. Our process provides collaboration and transparency that you’ve never seen in the industry. We’ll collaborate with you as if we were an extension of your own team, as we believe that immersing ourselves in your world is the most effective method to provide a product that fulfills your deadlines, stays under budget, and provides unrivaled quality to your end-users.

6. Big Picture Vision Yet Detail-oriented

While paying attention to detail is vital, big-picture thinking contains an overview of the supply chain’s links, as well as the mental ability to anticipate and resolve difficulties across the board. Maintaining focus on the goal requires both discipline and innovation. No matter you require a plastic injection mold made to run at your facility or thousands of excellent finished items packed in gift boxes for container loading, GEMS-MFG is confident to be a fantastic asset to your supply chain management.

Critical Approaches for Supply Chain Excellence

- Offering solutions that assist our clients in resolving their most challenging technology bottleneck

- Lean production is being implemented to help the flow of value-added work through the value streams

- Taking the advantages of our network of suppliers to provide our customers with a consistent experience and value

- Leveraging our know-how history of exceptional technology expertise and solid manufacturing experience

- Investing in areas like talent and facilities that can assist our clients launch products in the future.

- Obtaining and maintaining industry certifications to ensure that everything we do is of the highest quality and safety.

- Taking consumer feedback and turning it into actions that improve the way we serve our customers

Specific Aspects Of Our Supply Chain Management

- BOM analysis and optimization

- Raw material sourcing and distribution

- Component & assemblies engineering

- Multiple manufacturing solutions

- Mold, Tool and Die

- Mechanical assemblies

- Injection molded components

- Stampings & Castings

- Electronics PCBA

- Cables and wire harness assemblies

- Package materials

- Economies of scale for purchasing and manufacturing

- Forecast, production and delivery plan

- Product life cycle management

- Cross vendor management

- Warhousing and shipments consolidation

- Global logistics distribution according to customer needs