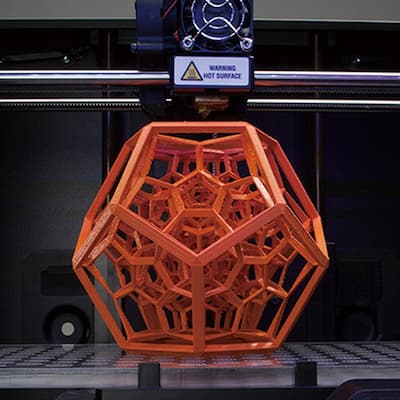

1. Custom Rapid Prototyping

Rapid Prototyping is a critical step in the product development process at GEMS-MFG. By leveraging advanced 3D printing, CNC machining, and rapid tooling technologies, we are able to quickly create functional prototypes in a variety of materials, including Metal, Plastic, and Silicone. This enables our clients to test and refine their designs before committing to production tooling, ensuring that the final product performs as expected.

Our Rapid Prototyping services are tailored to meet the specific needs of each project, from early-stage concept models to fully functional, pre-production prototypes. By iterating rapidly on designs, we help clients reduce development time, mitigate risks, and accelerate time-to-market for their products.

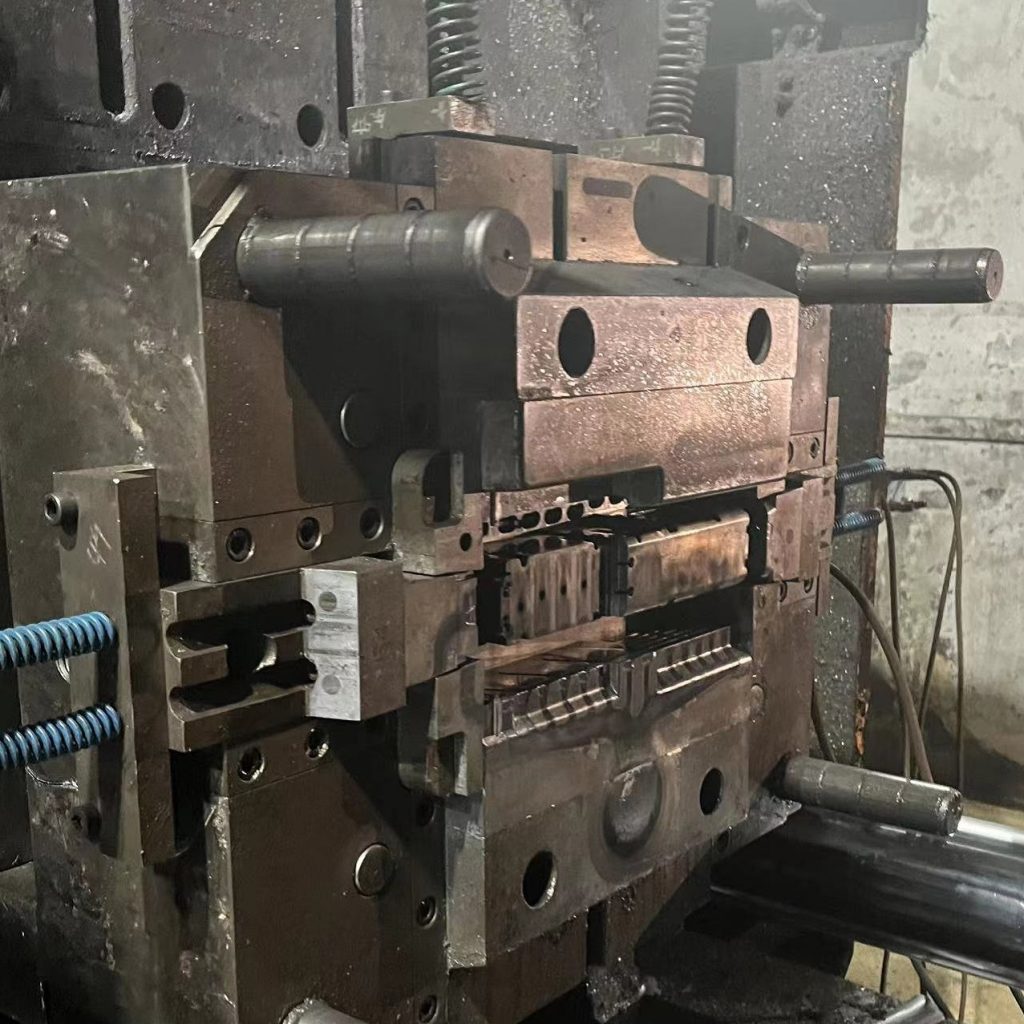

2. Mold Making for Precision Parts

GEMS-MFG’ Mold Making services provide the foundation for high-quality production in both Injection Molding and Die Casting. We design and manufacture custom molds with tight tolerances to ensure consistent quality across production runs. Our mold-making process emphasizes precision, material optimization, and durability, enabling clients to produce high-volume parts with minimal defects.

The GEMS-MFG team is skilled in applying Design for Manufacturability (DFM) principles to ensure that molds are designed for ease of use, reduced maintenance, and enhanced cycle times. This focus on mold design efficiency translates into significant cost savings for our clients, particularly in large-scale manufacturing projects.

Whether for intricate plastic parts or high-performance metal components, our mold-making capabilities are backed by years of expertise and a commitment to producing molds that maximize production efficiency and product quality.

3. Injection Molding and Compression Molding

Our Injection Molding services are ideal for producing complex, high-precision plastic parts in a variety of thermoplastic materials. We specialize in producing components for industries such as medical devices, automotive, and electronics, where accuracy and consistency are vital. Using state-of-the-art injection molding machines, we manufacture parts with intricate geometries, tight tolerances, and excellent surface finishes.

For projects requiring silicone components, GEMS-MFG offers Compression Molding services that provide high-quality parts with excellent durability and flexibility. This process is particularly suited to applications requiring heat-resistant or chemically inert parts, such as seals, gaskets, and medical-grade silicone products.

With both Injection and Compression Molding, we focus on optimizing cycle times, reducing material waste, and delivering high-quality parts that meet client specifications. Our expertise in material selection and process optimization ensures that each part performs reliably under demanding conditions.

4. Die Casting for Complex Metal Parts

GEMS-MFG’ Die Casting services offer precision metal components made from materials such as aluminum, zinc, and magnesium. Die Casting is an ideal solution for high-volume production of metal parts with complex geometries and stringent strength requirements. GEMS-MFG excels in producing lightweight, durable parts that meet the mechanical performance and aesthetic needs of industries like automotive, aerospace, and consumer electronics.

Our expertise in the die-casting process allows us to achieve tight tolerances and intricate details that would be difficult to replicate with other manufacturing methods. Additionally, our die-casting services include secondary operations like trimming, machining, and surface finishing to ensure that the final product meets exacting client specifications.

5. CNC Machining for Precision Manufacturing

CNC Machining at GEMS-MFG enables us to deliver highly precise, custom parts from a wide range of materials, including metals, plastics, and composites. Using advanced multi-axis CNC machines, we produce parts with complex geometries, tight tolerances, and high-quality surface finishes, making it a versatile solution for prototyping and production.

Our CNC machining services support industries that require precise, reliable parts, such as medical devices, aerospace, and industrial machinery. Whether for small-batch prototypes or large-scale production, GEMS-MFG’ CNC machining capabilities ensure that each part meets the highest standards of quality, durability, and performance.

By offering CNC machining alongside our other manufacturing services, we provide clients with the flexibility to choose the best manufacturing method for their specific project needs, all while maintaining the quality and consistency GEMS-MFG is known for.

6. Finished Product Assembly and Value-Added Services

At GEMS-MFG, we don’t just manufacture individual parts—we also offer comprehensive Finished Product Assembly services. From sub-assemblies to fully assembled products, our assembly capabilities ensure that every part integrates perfectly into the final product. By handling the complete assembly process, we eliminate the need for our clients to manage multiple suppliers, resulting in faster turnaround times and streamlined logistics.

In addition to assembly, we offer a range of value-added services, including Sheet Metal Stamping, Cable and Wire Harness assembly, PCBA (Printed Circuit Board Assembly), and Packaging. These services allow clients to receive complete, ready-to-sell products that meet the highest standards of quality and functionality. Our goal is to provide a fully integrated manufacturing solution that simplifies the supply chain while enhancing product performance and reliability.