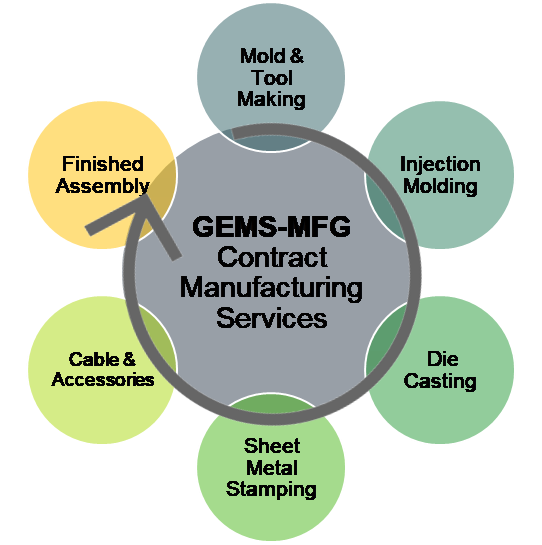

Custom Metal, Plastic & Silicone Parts’ Manufacturing Solutions And Finished Assembly Integration Services

A growing global market demand combined with a rapidly upgrading standard for products has meant that manufacturers are continuously striving to create solutions that are stronger, lighter and more cost-effective, while also offering excellent aesthetics, functionality, performance, energy and resource efficiency.

When you choose GEMS Manufacturing, you get an expert partner through the entire production cycle, taking your product from concept to reality.

Your core capabilities should be the focus of your business. We can provide direct distribution of the electronic and mechanical products we manufacture or assemble, helping our customers to streamline their supply chain and eliminate unnecessary touch points for our componenet and finished assemblies and other products. Whether you need one specific part only or a complete turnkey solution, we have the facilities, the employees, and the experience to get it done right, on time, and in a cost-efficient manner. For your next project, let GEMS lend you a hand.

GEMS offers tailor-made manufacturing solutions for these requirements, with a broad portfolio of Metals, Plastics and Silicones integration services that supports the fulfillment of customers’ unique needs. High precision metal, plastic & silicone rubber parts’ manufacturing, custom cable and finished assembly are at our business core! We are proud of delivering molds, parts, sub-assemblies, finished products through our contract manufacturing services in the consumer appliances, business machines, healthcare, home automation, life science and automotive sectors.

Benefits Of Contract Manufacturing You May Gain Through Working With GEMS-MFG

1. Less Suppliers

GEMS is capable of building wide ranges of components, sub-assemblies and assemblies, as well as finished units with customized packaging box build.

2. Reduced Cost

Get more of your products built together, avoiding multiple marks up from multiple suppliers. Also following lean production to eliminate wasteful activities is crucial to increase profitability.

3. Upgraded Quality

Quality control instruction is to set up following your product specification. Box builds that should have been inspected by GEMS will arrive at your facility ready to install.

4. Shorter Lead Time

GEMS will work with you to plan shorter lead time. We have wide ranges of in-house production facilities and reliable outsourced supports for quick turnaround and maximum flexibility.

Above all, please contact us directly to learn more about our manufacturing services for mold building, injection molding, die casting and sheet metal stamping products or any of our other fabrication capabilities. To find out how we can help your business, please feel free to submit a request for quote.