I. Introduction

Threaded plastic parts are widely used across industries such as packaging, automotive, medical devices, and consumer goods. From bottle caps and dispensing closures to syringe fittings and automotive connectors, these components often rely on precise screw threads for assembly and functionality.

However, molding screw threads in plastic presents a unique challenge. Unlike simple shapes that can be ejected directly with standard ejector pins, threaded parts cannot be removed straight from the mold without damage. The thread geometry locks the part onto the mold core, making conventional ejection methods impractical.

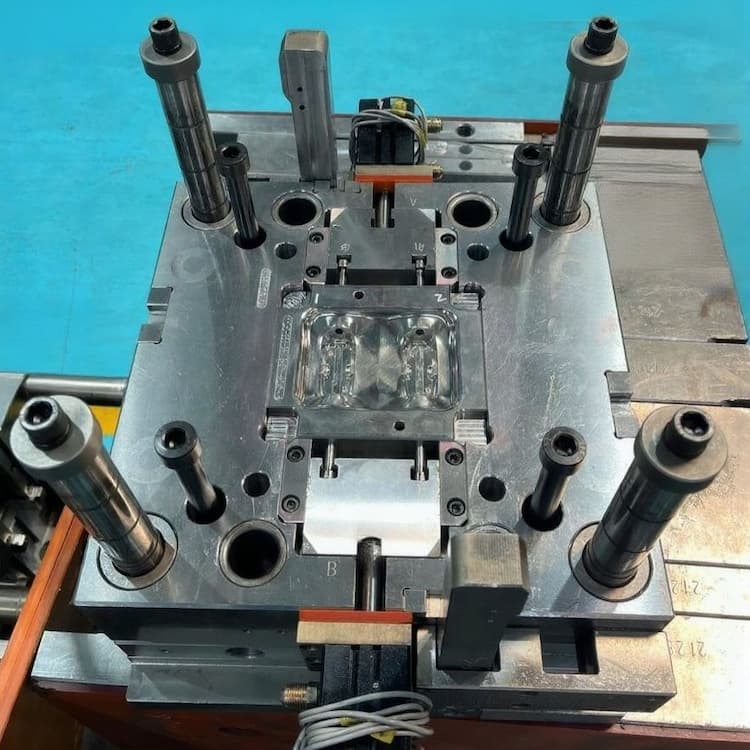

To solve this problem, injection molds often incorporate core pulling mechanisms, especially screw thread core pulling systems. These mechanisms allow the threaded core to rotate or withdraw in a controlled manner during mold opening, releasing the plastic part smoothly without deforming or damaging the threads. This makes screw thread core pulling structures a critical design feature in molds that produce threaded plastic components, enabling high-volume, high-precision, and repeatable manufacturing.