VIII. Applications of Clear and Transparent Plastic Injection Molding

Clear and transparent plastic injection molding offers a versatile solution for creating high-performance products across various industries. The ability to produce parts with exceptional clarity and precision makes it a go-to method for applications that demand transparency, durability, and aesthetic appeal. Here are some key areas where clear plastic injection molding excels:

- Medical and Healthcare Devices

Clear plastics like Polycarbonate (PC) and PMMA are commonly used in medical device manufacturing due to their excellent optical clarity and high impact resistance. Applications include syringe bodies, diagnostic equipment housings, fluid bags, and hearing aids, where transparency is essential for visual inspection, monitoring, and patient safety.

- Automotive and Transportation

In the automotive industry, clear plastic injection molding is used to produce components like headlamp lenses, light covers, and instrument panels. Transparent plastics provide durability, resistance to UV degradation, and clarity, all of which are crucial for both aesthetic and functional purposes in automotive lighting and displays.

- Consumer Electronics

Transparent plastics are used in consumer electronics for screens, casings, and display windows. Smartphones, tablets, and appliances often incorporate clear plastics for their front covers or control panels. Their optical clarity and impact resistance are essential for both aesthetics and functionality, ensuring the durability of delicate components like touchscreens.

- Packaging Solutions

Clear plastic packaging is widely used in industries such as food and beverage, cosmetics, and pharmaceuticals. Injection-molded clear plastic containers, bottles, and blister packs allow for product visibility while providing a barrier against contamination. Materials like PET are especially popular for packaging due to their strength and clarity.

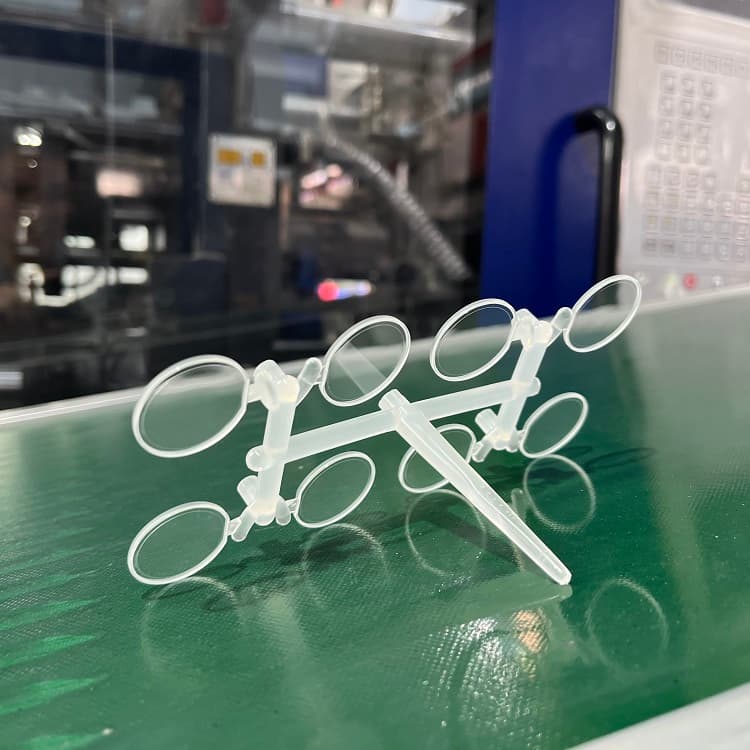

- Optical Lenses and Light Guides

Clear and optical-grade plastics are frequently used in optical applications, such as camera lenses, light guides, and optical windows. These materials are designed to meet stringent clarity, dimensional stability, and scratch resistance requirements, ensuring high-quality performance in devices like cameras, scanners, and optical instruments.

- Lighting Fixtures

Clear plastic injection molding is essential for producing lighting components such as diffusers, lens covers, and reflectors. Transparent materials like Polycarbonate and Acrylic provide excellent light transmission while offering resistance to UV radiation and weathering, making them ideal for indoor and outdoor lighting applications.

- Consumer Goods and Housewares

Many household products benefit from clear plastic injection molding, including storage containers, household appliance covers, and decorative items. Transparent plastics are valued for their clean, modern appearance, as well as their ability to withstand daily use.

- Point-of-Sale Displays

Clear plastics are often used in the creation of retail displays, showcasing products in a visually appealing manner. Injection-molded display cases, stands, and signage benefit from the transparency of materials like Acrylic, which helps capture attention while offering durability and clarity.

- Aerospace and Aviation

In the aerospace industry, clear plastics are used for cockpit windows, instrument covers, and exterior lighting components. These parts require high optical clarity and impact resistance to ensure safety and optimal performance in demanding environments.

- Architectural and Decorative Elements

Transparent plastics are increasingly used in architecture and interior design for applications like windows, skylights, partitions, and furniture accents. Their light-transmitting properties and aesthetic appeal make them an attractive choice for creating functional and visually striking elements in modern architecture.