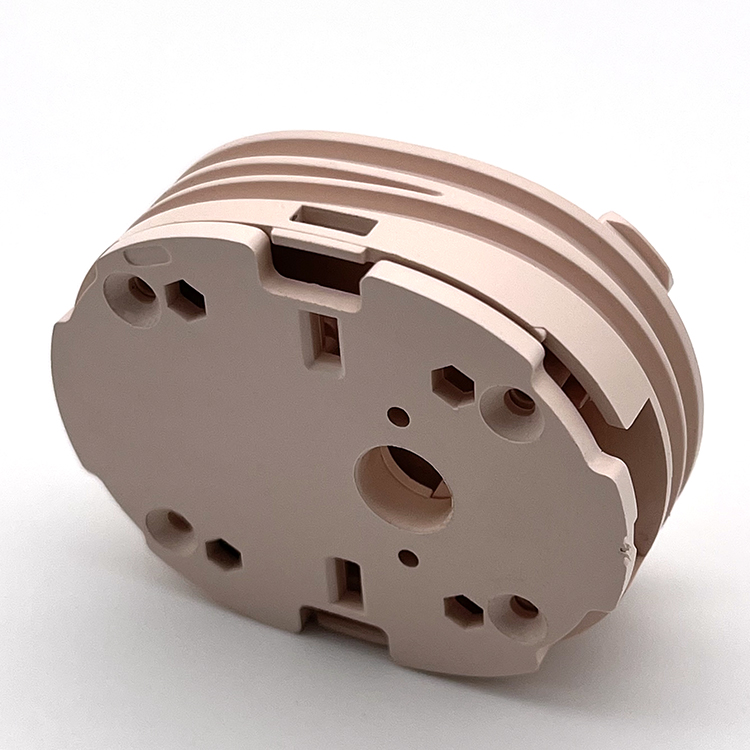

Plastic parts can be made in a wide range of shapes and sizes, from simple design to highly complex geometry, which allows them to be used in varied industries like consumer, healthcare, automotive, and medical and etc. With our combined experience and knowledge, GEMS-MFG has been providing plastic injection molding products to many clients for the past 25 years.

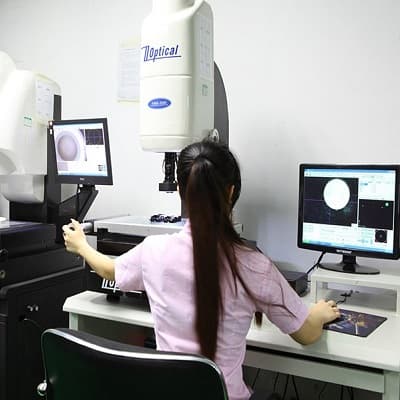

With in-house 37 injection molding machines ranging from 80 tons to 320 tons, we focus on the scientific molding of plastic injection approach, giving us greater production control than traditional molding methods, which may save significant amount of time, money and material for the customers. Below are some common materials used in our factory, such as PC, PET, PP, PBT, PS, ABS, PA, POM, PC, and many more.

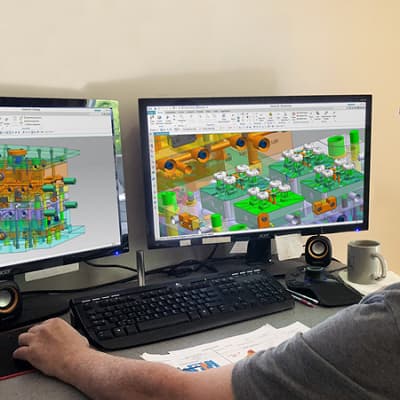

Following to your AutoCAD, IGES, PDF, or SolidWorks files, our experienced manufacturing team is capable of making your custom products strictly to the specification and quality standards. No matter how complex your design is, we’ll devote ourselves to find the most efficient manufacturing solution to satisfy your needs. Get in touch with us GEMS-MFG immediately to fulfill your product demand with the full support of our capabilities.

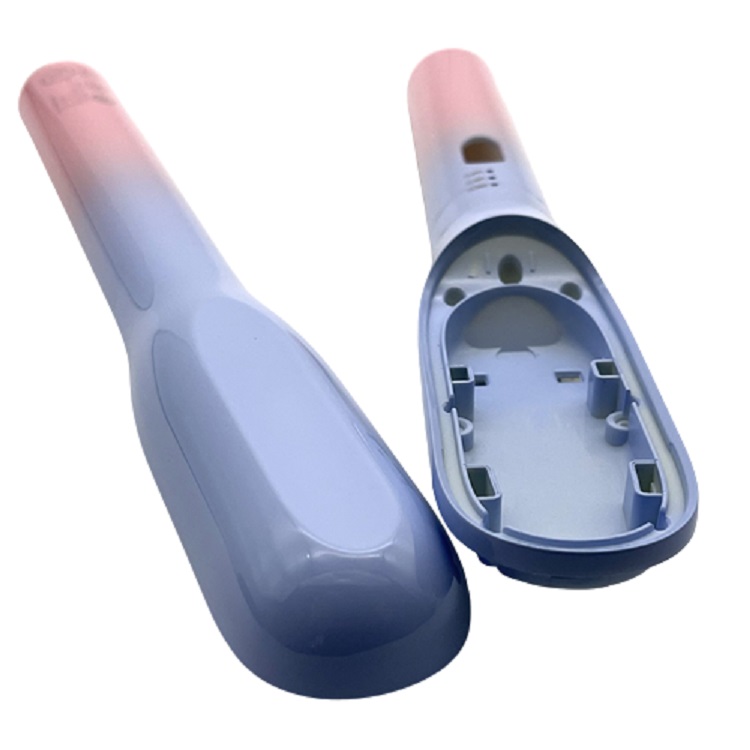

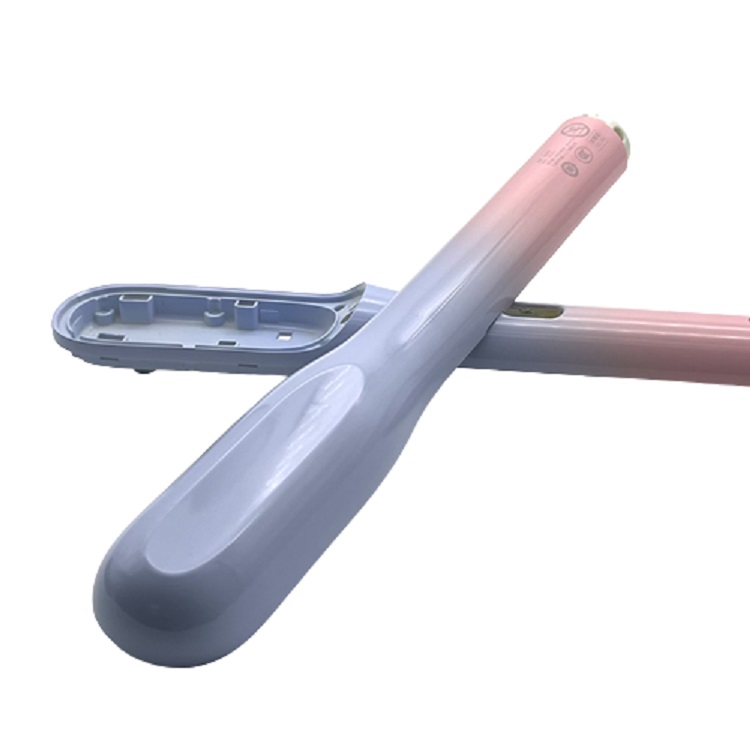

UNIQUE DESIGN PERSONAL CARE PRODUCT PARTS PLASTIC INJECTION MOLDING

UNIQUE DESIGN PERSONAL CARE PRODUCT PARTS PLASTIC INJECTION MOLDING HIGH PRECISION TWO SHOT INJECTION MOLDING SUPPLIER

HIGH PRECISION TWO SHOT INJECTION MOLDING SUPPLIER CHINA MOLD MAKING SUPPLIER PLASTIC INJECTION OVERMOLDING PARTS

CHINA MOLD MAKING SUPPLIER PLASTIC INJECTION OVERMOLDING PARTS HIGH QUALITY AUTOMOTIVE INTERIOR PLASTIC PARTS

HIGH QUALITY AUTOMOTIVE INTERIOR PLASTIC PARTS HYDRAULIC CYLINDER PULLING CORE THREAD INJECTION MOLDING PARTS

HYDRAULIC CYLINDER PULLING CORE THREAD INJECTION MOLDING PARTS