or View Manufacturing Services

GEMS-MFG Is Built on 5 Core Numbers

600+

Global Clients

Served

10,000+

Workshop Square

Meter

200+

Skillful Production

Operators

120,000+

Unique Products

Delivered

120+

Partnership Suppliers

Cooperated

GEMS-MFG Services

Why GEMS-MFG

We are your one-stop manufacturing solution provider for customized products with the joint effort & support from our 120 partnership subcontractors mainly for the production of metals & plastics. We can expand much faster but the top management decide to keep GEMS a compact, dedicated and professional company, which allows our team to really focus and deliver on your projects without any excuse or compromise. We strive to be a long-term, reliable and trustworthy partner of our customers rather than just being a contractor, and look forward to growing the company with customers’ success.

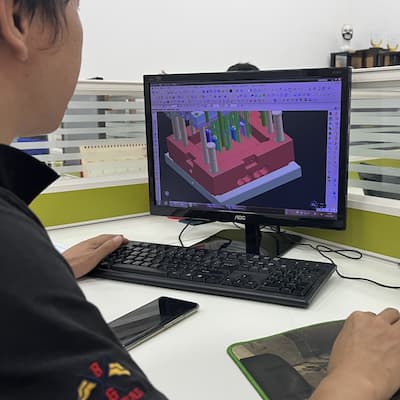

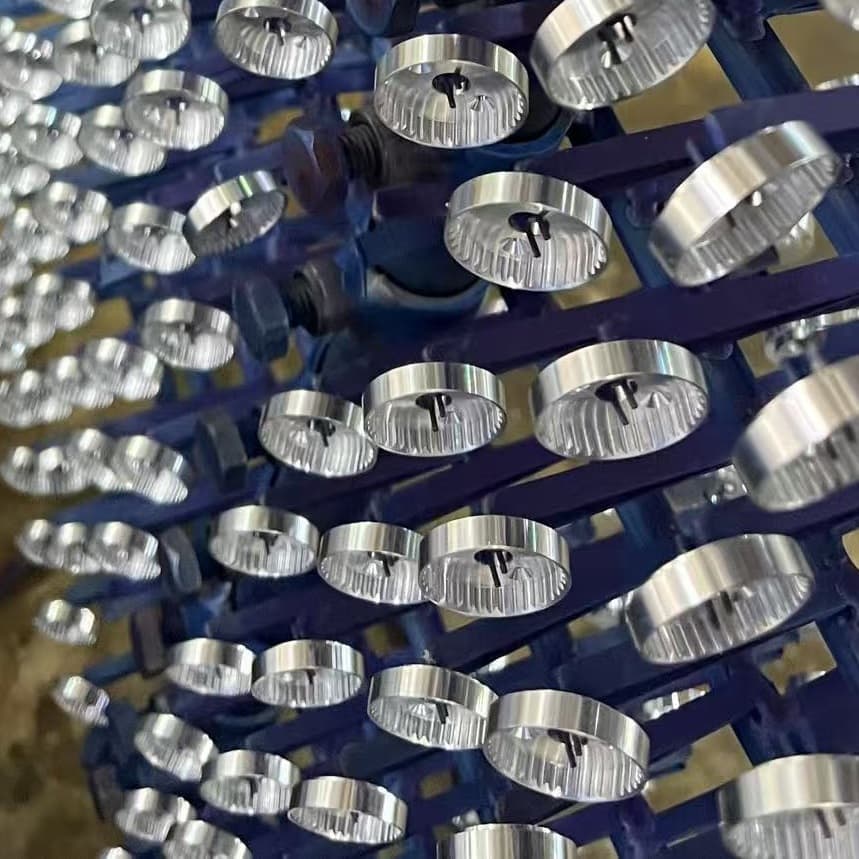

With the passing years, we are proud to build up a manufacturing veteran team with rich experience and full expertise to fulfill your specific demand. From mold making, injection molding, die casting, stamping and sheet metal, to 2nd processes like CNC machining, oil spraying, powder coating and chrome plating, and then assembling and packaging and related, we always have someone in house to be an expert to resolve the issues in different stages of product development. We also specialize in providing charger, cable and hub, plus other electronic accessories that support a complete set of product.

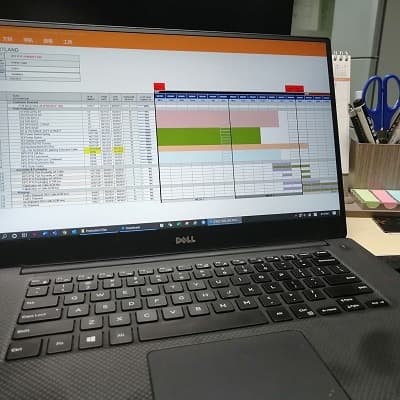

“Think global, execute local” is the principle of our work. Time, quality and cost are the three key elements to be considered throughout the product development from concept design to mass production. A detailed plan with weekly conference call update is a critical gateway to ensure these three key elements are successfully implemented, also assuring that all parties are on the same page. Communication is the Secret to Success . Everyone works independently to take care his own job, but together we are a team to get things done and are your daily eyes and ears onsite in China.

We offer a wide variety of products, such as mold, component and assembly product, and certain value-added services. For logo or branding product, we have in house resources to complete a color mix that can perfectly match a brand’s unique colors in fast and cost-effective way. Understood the client needs production parts but having a hard time to find a vendor since the order quantity is as low as 1000 or lower. GEMS is well set up for low volume injection molding or die casting projects. Surely our team is also capable of building SPI Class 101 mold that is designed & made for 1 million cycles or more of producing the same high quality parts consistently.

How GEMS-MFG Works

With abundant experience in custom manufacturing field, GEMS-MFG works closely with all the customers to provide the best manufacturing solutions in an efficient manner. The company also implements processes and procedures to ensure each project completes on time and within budget, as well as upholds the highest quality standards to the product specification. See our workflow in details below.

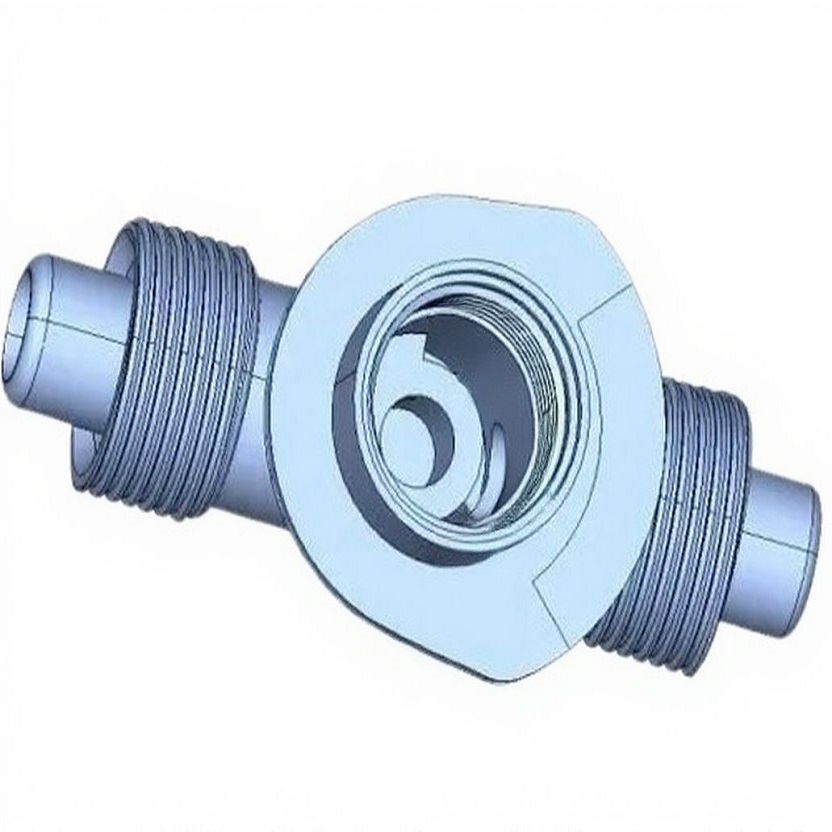

Send your product CAD and specification for our engineering review and cost estimation. It depends on the complexity of the part or project, generally we will quote within 24 hours upon receiving your enquiry, but for complex parts we may ask for additional information and provide complete quotation within 3 working days.

Listen and probe to identify the customer’s needs, and firm up the ideal manufacturing process. Choosing the exactly right manufacturing solution can be a challenging job, as there are a number of processing options to choose from, while each with individual benefits and drawbacks. Obviously, it is a combination of solid experience, broad knowledge and operational efficiency.

Upon approval from customer, we immediately start the production and report the progress. At GEMS-MFG, our core manufacturing scope consist of Mold Making, Injection Molding, Die Casting, Sheet Metal Stamping and Finished Assembly, as well as other value added services that play as part of our integrated capabilities.

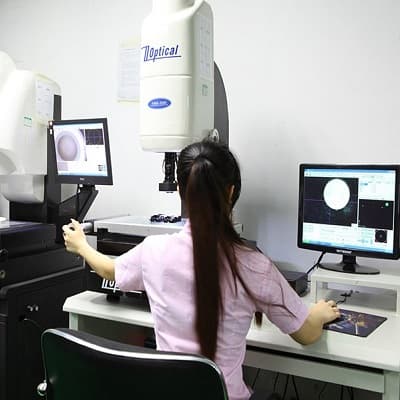

Following the specification, all batches of products are inspected and recorded before shipping. Setting up strict quality control process for a product is one critical thing you need to consider as soon as you plan to make it from concept into reality, which will allows you to prevent or overcome all day-to-day quality issues with ease and grace.

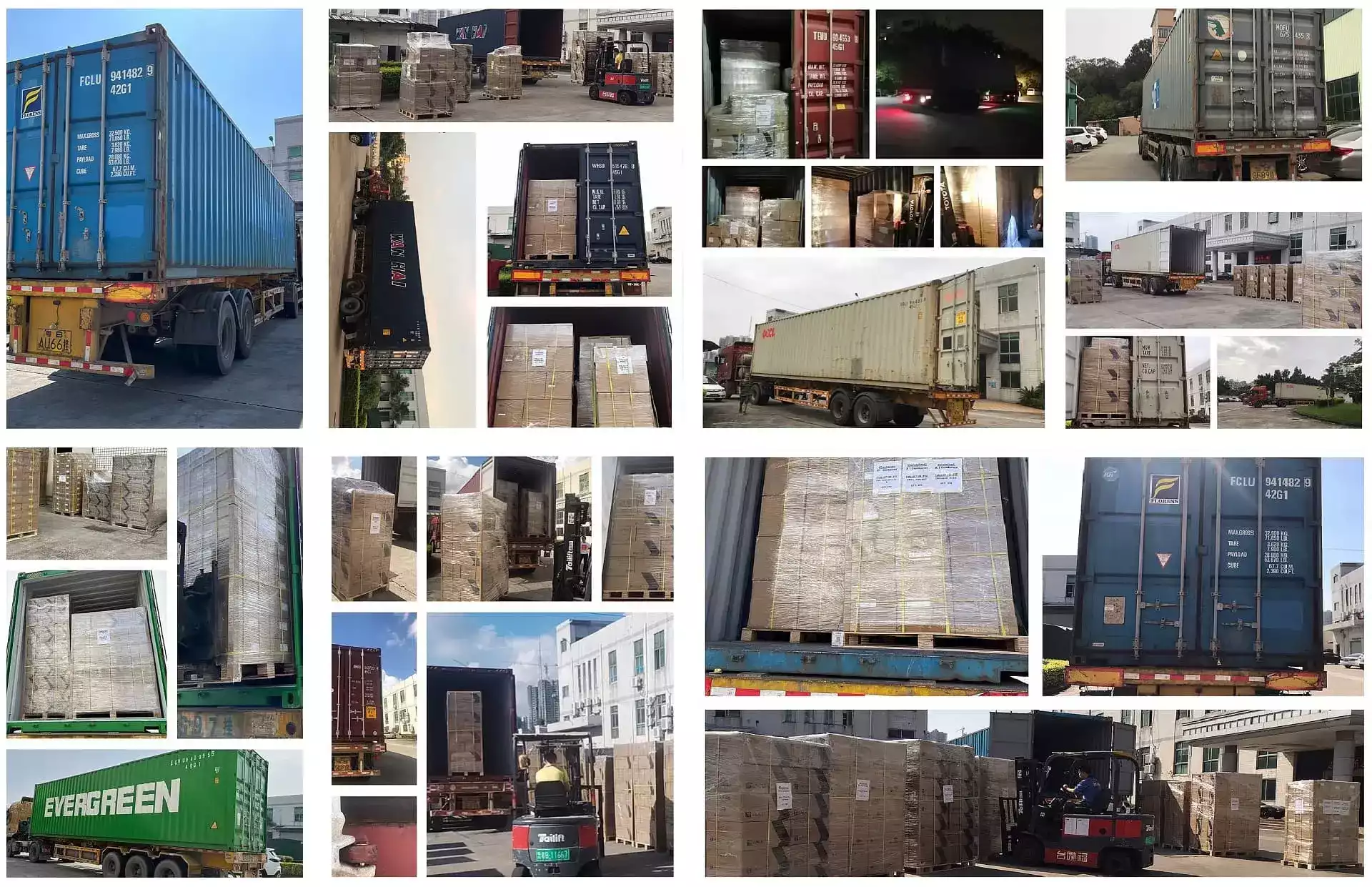

GEMS-MFG support packaging and delivery services for molds, parts, sub-assemblies or/and finished products to clients worldwide. It is worthwhile to take the time to select the appropriate packaging and employ practical shipping methods, so as to assure the product will arrive at assigned destination in good condition at lowest cost.

GEMS-MFG Order Fulfillments

The ability of order fulfillment is not just about the demand of a single piece, but also about the quality and how much money you may save in the long run cooperating with GEMS-MFG. By emphasizing Quality First we have established a culture that can offer the better quality you need at today’s quick innovation pace, which is a crucial aspect of our Global Excellence Manufacturing Solutions.

Latest Blog Posts

Welcome to our Latest Blog Posts, where we embark on a journey of exploration, innovation, and expertise. Dive into a wealth of insights and knowledge crafted by our experienced professionals, covering a spectrum of topics that resonate with the pulse of industry trends and advancements. Join us in this intellectual odyssey that every post is a step toward staying ahead, gaining fresh perspectives, and fostering a deeper understanding of the dynamic world we operate in.